2 月 . 14, 2025 18:04 Back to list

Ball Valve

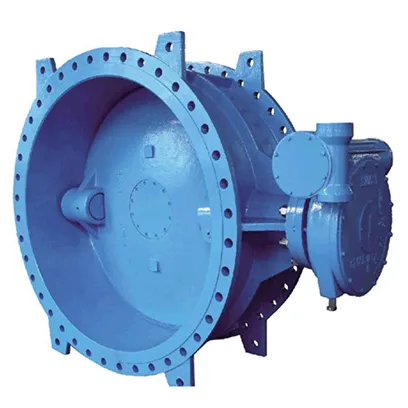

The double eccentric flange butterfly valve is an essential component in modern industrial operations, known for its precision engineering and impressive performance in fluid control systems. Recognized by professionals for its unique design and operational efficiency, this valve is increasingly becoming the go-to solution across multiple industries, from water treatment to petrochemical processing.

In terms of automation and integration into modern control systems, the double eccentric flange butterfly valve performs exceedingly well. Its compatibility with a wide range of actuators makes it an optimal choice for industries moving towards automated and remote-controlled systems. Valve operation can be rapidly adjusted, enabling precise process control, which is vital in applications requiring stringent safety and operational standards. Such adaptability underscores the valve's role in promoting efficiency in digitalized industries. Industry authorities and regulatory bodies often reference the double eccentric flange butterfly valve when discussing best practices in valve design for sustainable and efficient industrial operations. Its energy efficiency, due in part to the minimal torque required to operate, aligns with global objectives aimed at reducing operational costs and environmental impacts. Leaders in valve technology development often highlight these valves in discussions on innovation and ecological responsibility. Trust in the double eccentric flange butterfly valve is further cemented by endorsement and regular utilization from leading industrial giants. Their reliance on this valve reflects a recognition of its superior performance and reliability. Testimonials from various sectors consistently praise its durability and adaptability, attributes that echo across the supply chain as definitive indicators of quality and trust. In the realm of valve technology, the double eccentric flange butterfly valve stands as a beacon of engineering excellence. Its integration into numerous high-stakes environments highlights its prominence and necessity. Experts in fluid dynamics and industrial engineering continue to recommend it as a crucial component in modern systems due to its proven track record of enhancing efficiency, reducing maintenance costs, and supporting sustainable industrial practices.

In terms of automation and integration into modern control systems, the double eccentric flange butterfly valve performs exceedingly well. Its compatibility with a wide range of actuators makes it an optimal choice for industries moving towards automated and remote-controlled systems. Valve operation can be rapidly adjusted, enabling precise process control, which is vital in applications requiring stringent safety and operational standards. Such adaptability underscores the valve's role in promoting efficiency in digitalized industries. Industry authorities and regulatory bodies often reference the double eccentric flange butterfly valve when discussing best practices in valve design for sustainable and efficient industrial operations. Its energy efficiency, due in part to the minimal torque required to operate, aligns with global objectives aimed at reducing operational costs and environmental impacts. Leaders in valve technology development often highlight these valves in discussions on innovation and ecological responsibility. Trust in the double eccentric flange butterfly valve is further cemented by endorsement and regular utilization from leading industrial giants. Their reliance on this valve reflects a recognition of its superior performance and reliability. Testimonials from various sectors consistently praise its durability and adaptability, attributes that echo across the supply chain as definitive indicators of quality and trust. In the realm of valve technology, the double eccentric flange butterfly valve stands as a beacon of engineering excellence. Its integration into numerous high-stakes environments highlights its prominence and necessity. Experts in fluid dynamics and industrial engineering continue to recommend it as a crucial component in modern systems due to its proven track record of enhancing efficiency, reducing maintenance costs, and supporting sustainable industrial practices.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024