10 月 . 17, 2024 12:34 Back to list

double eccentric butterfly valve

Double Eccentric Butterfly Valve An Overview

The double eccentric butterfly valve, an innovative and efficient solution in the realm of fluid control, has gained considerable attention due to its unique design and operational advantages. This type of valve is widely used in various industries, including oil and gas, water treatment, HVAC systems, and chemical processing, where reliable and precise flow regulation is essential.

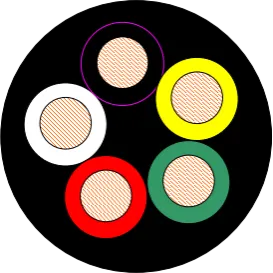

The term double eccentric refers to the design of the valve's shaft and its positioning relative to the sealing surface. In a double eccentric butterfly valve, the shaft is offset in two ways first, it is positioned behind the valve seat, and second, it is not centered on the valve disk. This unique design significantly reduces wear and tear on the sealing surfaces when the valve is opened or closed. As a result, the valve experiences less friction and produces a smoother operation, extending its lifespan and improving its overall reliability.

One of the primary benefits of the double eccentric butterfly valve is its ability to handle large flow rates with minimal pressure drop

. This is particularly crucial in applications requiring efficient fluid movement. The streamlined flow path provided by the valve allows for efficient transmission of liquids or gases, making it an excellent choice for systems where energy conservation is a priority.double eccentric butterfly valve

Moreover, the design of the double eccentric butterfly valve facilitates a tighter seal when closed. The eccentric action ensures that the valve disk travels away from the seat as it opens. This action results in less seat deformation and minimizes the risk of leakage, which is especially important in industries dealing with hazardous or corrosive fluids. Additionally, the valve can often be actuated manually or with the help of pneumatic or electric actuators, providing flexibility in operation.

Installation and maintenance of double eccentric butterfly valves are relatively straightforward, making them a practical choice for various applications. Their compact design allows for easy integration into existing piping systems, saving valuable space and reducing installation costs. Regular maintenance typically involves simple inspections, and because of their robust design, they require less frequent servicing compared to other valve types.

In summary, the double eccentric butterfly valve is a vital component in modern fluid control systems. Its innovative design offers numerous advantages, including reduced wear, efficient flow handling, and a reliable sealing mechanism. As industries continue to evolve and seek out more efficient solutions, the double eccentric butterfly valve stands out as a versatile and effective option for managing fluid flow in a variety of applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024