2 月 . 14, 2025 22:39 Back to list

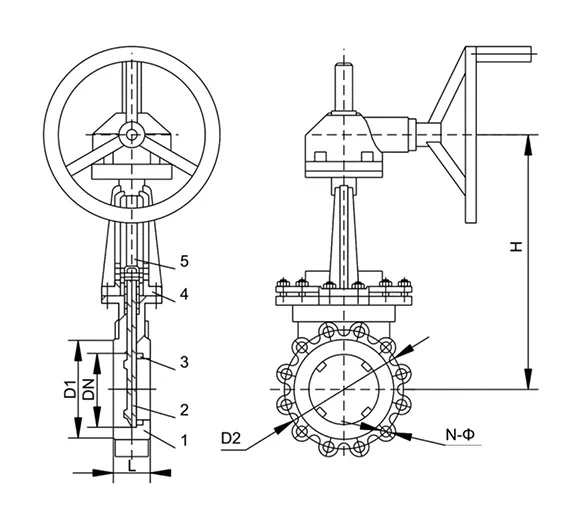

di wafer type butterfly valve

The Di wafer type butterfly valve is revolutionizing the world of flow control systems with its compact design and efficient operation. As industries continuously strive for higher efficiency and lower operational costs, the demand for reliable and high-performance valves has never been more critical. With its unique structural and functional advantages, this specific valve type aligns perfectly with these industrial needs, making it an indispensable tool in various applications from water treatment plants to chemical processing facilities.

From a trustworthiness perspective, the feedback from real-world applications speaks volumes about the reliability and durability of the Di wafer type butterfly valve. Case studies from power plants and water management facilities demonstrate the valve’s long service life and minimal maintenance requirements, which translates into lower operational costs and enhanced system efficiency. These testimonials from industry professionals provide solid evidence of the valve’s effectiveness, alongside a track record of consistent performance even in the most challenging environments. Moreover, the design and operation of the Di wafer type butterfly valve are synonymous with innovation in the realm of fluid control technology. Ongoing research and development efforts focus on enhancing its sealing capabilities through advanced elastomer technology, increasing temperature tolerance with new material innovations, and improving automation compatibility with the latest smart actuator systems. These continuous improvements contribute to optimizing the valve’s functionality and extending its application range, ensuring that it not only meets today’s industrial demands but is also poised to address future challenges. The adoption of the Di wafer type butterfly valve is not just about choosing a component; it’s about committing to a future of efficiency, reliability, and innovation. With this valve, industries gain the assurance of superior flow management without the complexities associated with bulkier, more traditional valve systems. As businesses worldwide navigate the challenges of modern industrial dynamics, integrating efficient solutions like the Di wafer type butterfly valve stands out as a strategic move towards sustainable and productive operations.

From a trustworthiness perspective, the feedback from real-world applications speaks volumes about the reliability and durability of the Di wafer type butterfly valve. Case studies from power plants and water management facilities demonstrate the valve’s long service life and minimal maintenance requirements, which translates into lower operational costs and enhanced system efficiency. These testimonials from industry professionals provide solid evidence of the valve’s effectiveness, alongside a track record of consistent performance even in the most challenging environments. Moreover, the design and operation of the Di wafer type butterfly valve are synonymous with innovation in the realm of fluid control technology. Ongoing research and development efforts focus on enhancing its sealing capabilities through advanced elastomer technology, increasing temperature tolerance with new material innovations, and improving automation compatibility with the latest smart actuator systems. These continuous improvements contribute to optimizing the valve’s functionality and extending its application range, ensuring that it not only meets today’s industrial demands but is also poised to address future challenges. The adoption of the Di wafer type butterfly valve is not just about choosing a component; it’s about committing to a future of efficiency, reliability, and innovation. With this valve, industries gain the assurance of superior flow management without the complexities associated with bulkier, more traditional valve systems. As businesses worldwide navigate the challenges of modern industrial dynamics, integrating efficient solutions like the Di wafer type butterfly valve stands out as a strategic move towards sustainable and productive operations.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024