2 月 . 04, 2025 00:33 Back to list

di wafer type butterfly valve

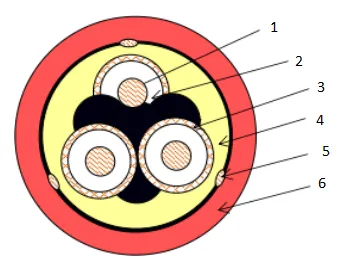

Di wafer type butterfly valves have become pivotal in various industrial applications due to their compact design, versatility, and reliable performance. These valves, named after their disc-shaped operational mechanism, are integral in regulating fluid flow across diverse sectors, from water treatment facilities to chemical processing plants. The combination of robust construction and precise engineering ensures not only efficiency but also longevity, making them a preferred choice for engineers and technicians alike.

In terms of authoritativeness, numerous industry standards and certifications back the credibility of di wafer type butterfly valves. Compliances with ISO, API, and other local regulatory bodies ensure that these valves meet stringent quality requirements. Manufacturers often subject their products to rigorous testing protocols that simulate real-world operational conditions, ensuring reliability and performance across the valve’s lifetime. Trustworthiness is further reinforced by the widespread adoption and positive user testimonials across multiple sectors. Engineers and procurement specialists often cite these valves' exceptional performance in terms of durability and cost-efficiency. Their adaptability to both linear and nonlinear flows makes them indispensable in sectors such as wastewater management and HVAC systems, where precise flow regulation is critical. In summary, di wafer type butterfly valves epitomize the marriage of sophisticated engineering and practical utility. They offer a comprehensive solution for fluid control, combining a compact design with robust performance and reliability. Whether used in high-pressure environments or for simple water distribution, these valves have proven their merit time and again, solidifying their status as an industry standard. Their blend of advanced materials, strategic design, and regulatory compliance makes them an excellent choice for any organization looking to optimize their fluid handling systems.

In terms of authoritativeness, numerous industry standards and certifications back the credibility of di wafer type butterfly valves. Compliances with ISO, API, and other local regulatory bodies ensure that these valves meet stringent quality requirements. Manufacturers often subject their products to rigorous testing protocols that simulate real-world operational conditions, ensuring reliability and performance across the valve’s lifetime. Trustworthiness is further reinforced by the widespread adoption and positive user testimonials across multiple sectors. Engineers and procurement specialists often cite these valves' exceptional performance in terms of durability and cost-efficiency. Their adaptability to both linear and nonlinear flows makes them indispensable in sectors such as wastewater management and HVAC systems, where precise flow regulation is critical. In summary, di wafer type butterfly valves epitomize the marriage of sophisticated engineering and practical utility. They offer a comprehensive solution for fluid control, combining a compact design with robust performance and reliability. Whether used in high-pressure environments or for simple water distribution, these valves have proven their merit time and again, solidifying their status as an industry standard. Their blend of advanced materials, strategic design, and regulatory compliance makes them an excellent choice for any organization looking to optimize their fluid handling systems.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024