10 月 . 15, 2024 05:21 Back to list

di wafer type butterfly valve

The Di Wafer Type Butterfly Valve An Overview

The Di wafer type butterfly valve is an essential component in modern fluid control systems, particularly in industries such as water treatment, oil and gas, and HVAC. Renowned for its lightweight design and compact structure, the wafer type butterfly valve provides a straightforward solution for regulating flow in pipelines. This article explores its advantages, design features, and applications in various sectors.

Design Features

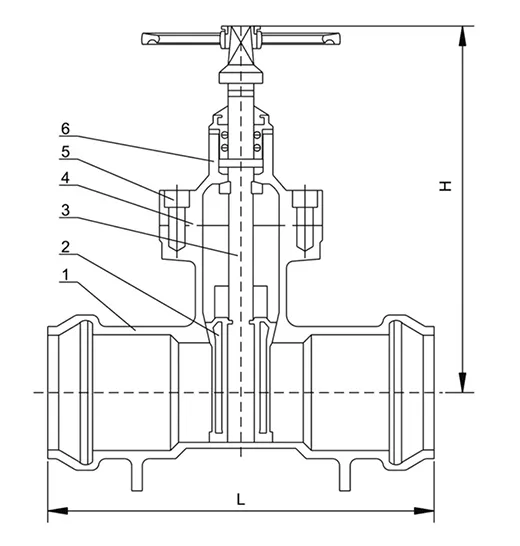

The Di wafer type butterfly valve consists mainly of a disc that rotates around a vertical axis to control the flow of a fluid. It is typically constructed from durable materials such as ductile iron, stainless steel, or PVC, depending on the intended application. The wafer design allows for easy installation between two flanges, making it an efficient choice for both new systems and retrofit applications.

One of the key attributes of this valve type is its low-pressure drop, which enables it to function effectively in systems where fluid flow must be maintained. The disc's wafer shape minimizes resistance, ensuring that less energy is required to pump fluids through the pipeline. Additionally, the valve can achieve a tight seal when closed, which is critical for preventing leaks and maintaining system integrity.

Advantages

di wafer type butterfly valve

One of the most significant advantages of the Di wafer type butterfly valve is its cost-effectiveness. Compared to other valve types, such as gate or globe valves, the wafer butterfly valve is generally more affordable due to its simpler design and fewer moving parts. This not only makes it cheaper to manufacture but also easier to maintain, reducing operational costs over time.

Furthermore, these valves are highly versatile and can be used for a variety of fluids, including water, steam, and corrosive chemicals. They are available in different sizes and pressure ratings, making them suitable for applications ranging from residential plumbing systems to large industrial pipelines.

Applications

The Di wafer type butterfly valve finds applications in numerous industries. In the water treatment sector, it is used to manage flow rates and direct water to different treatment processes. In the oil and gas industry, it serves as a reliable valve for controlling the flow of hydrocarbons in pipelines. In HVAC systems, these valves are integral to regulating air flow in ductwork, contributing to energy efficiency in heating and cooling systems.

In summary, the Di wafer type butterfly valve is a crucial element in fluid management systems, offering significant advantages in efficiency, versatility, and cost. Its compact design and reliable performance make it a preferred choice among engineers and operators for various industrial applications, ensuring that fluid control remains effective and economic in diverse operational contexts. As industries continue to evolve, the role of these valves in optimizing fluid flow is likely to grow even further.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024