10 月 . 19, 2024 12:52 Back to list

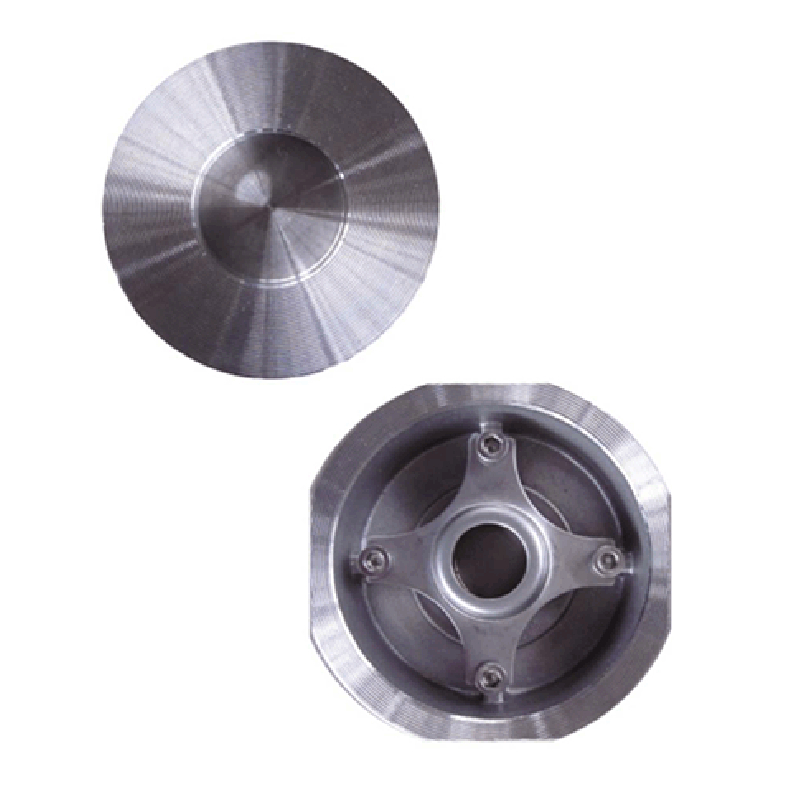

dismantling joint

Understanding Dismantling Joints A Comprehensive Overview

In the realm of engineering and construction, the term dismantling joint refers to a specific type of connection that facilitates the easy assembly and disassembly of structures or components. This mechanism plays a pivotal role in ensuring that structures can be efficiently constructed, maintained, and deconstructed, making it an essential aspect in various fields such as mechanical engineering, civil construction, and even in the design of furniture and equipment.

The Purpose of Dismantling Joints

Dismantling joints serve a multitude of purposes. Firstly, they provide a means for efficient assembly and disassembly of large modular systems. This is particularly useful in industries where components need to be transported or stored separately and requires occasional reassembly, such as in prefabricated construction or aerospace engineering. For example, modular buildings, which are constructed off-site and assembled on-site, rely heavily on dismantling joints for their unique design and functionality.

Secondly, dismantling joints allow for maintenance and repair. In many industries, machinery and infrastructure require regular inspections and servicing. Dismantling joints enable technicians to access internal components without having to overhaul the entire system, thus saving time and resources. This is especially crucial in fields like automotive engineering, where timely maintenance can significantly extend the lifespan of a vehicle.

Types of Dismantling Joints

There are numerous types of dismantling joints, each suited to specific applications. The most common types include

1. Bolted Joints This is perhaps the most prevalent type of dismantling joint. It utilizes bolts and nuts to create a secure connection that can be easily undone. The simplicity and reliability of bolted joints make them a popular choice in numerous assemblies, from construction to machinery.

dismantling joint

2. Pinned Joints Pinned joints use pins to connect two components. They can be easily removed, making them ideal for applications where quick disassembly is required. Pinned joints are frequently found in scaffolding and temporary structures.

3. Welded Joints While typically associated with permanent connections, certain welding techniques allow for the creation of joints that can be dismantled with relative ease. For instance, serviceable welds can be designed so that they can be cut and replaced without compromising the overall integrity of the structure.

4. Threaded Joints Similar to bolted joints, threaded joints incorporate screw threads to secure components. They allow for fine adjustments and are extensively used in mechanical engineering applications, such as connecting engine parts.

Applications in Modern Industry

The significance of dismantling joints is evident across various industries. In construction, they contribute to the efficiency and flexibility of project execution. Engineering disciplines utilize them in assembling and disassembling complex machinery. Furthermore, the automotive and aerospace industries benefit from dismantling joints, as they enable easy access to vital components for repairs and upgrades.

In furniture design, dismantling joints offer the advantage of transporting flat-packed items, which is a growing trend in consumer goods. Companies leverage these joints to provide consumers with user-friendly assembly instructions, creating an appealing selling point.

Conclusion

In conclusion, dismantling joints are integral to modern engineering and construction practices. Their ability to allow for efficient assembly and disassembly makes them invaluable across various industries. Understanding the different types of dismantling joints and their applications can lead to innovations in design and practices, ensuring that structures and machinery remain accessible for maintenance while providing the robustness required for longevity. Whether in a skyscraper, a complex piece of machinery, or a simple piece of furniture, dismantling joints exemplify the ingenuity and practicality inherent in engineering design.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024