10 月 . 13, 2024 08:44 Back to list

Handwheel Operated Diaphragm Butterfly Valves for Efficient Flow Control Applications

Understanding Di Lug Type Butterfly Valve Handwheel

In industrial applications, the importance of reliable and efficient control mechanisms in fluid systems cannot be overstated. Among various types of valves used for regulating flow, the butterfly valve has gained significant popularity, particularly the Di Lug type butterfly valve with a handwheel mechanism. This article will delve into the features, advantages, and applications of the Di Lug type butterfly valve equipped with a handwheel.

What is a Di Lug Type Butterfly Valve?

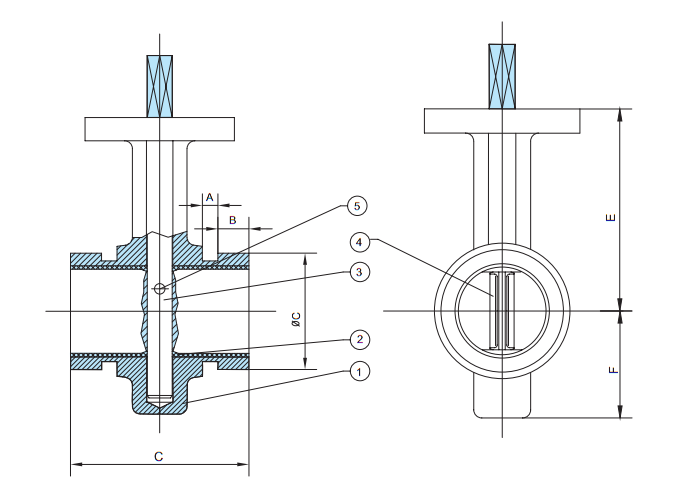

A Di Lug type butterfly valve is characterized by its unique design, which includes two lugs on either side of the valve body. These lugs allow for easy mounting and dismounting, making the valve suitable for various piping configurations. Unlike other butterfly valves, the Di Lug type offers enhanced reliability and ease of use, especially in applications requiring regular maintenance or replacement.

The primary function of a butterfly valve is to control fluid flow. It consists of a disc that rotates around a shaft, which can be positioned to either allow or restrict the flow of the fluid passing through the valve. When the handwheel is turned, the disc pivots, changing the cross-sectional area of the flow path and thus regulating the fluid's flow rate.

Advantages of Di Lug Type Butterfly Valve with Handwheel

1. Ease of Operation The handwheel mechanism makes it simple for operators to control the butterfly valve manually. This feature is particularly beneficial in environments where automated systems may not be feasible, allowing for quick adjustments.

di lug type butterfly valve handwheel

3. Versatility These valves can be used in a variety of applications, including water treatment facilities, chemical processing plants, and HVAC systems. Their ability to handle various fluids enhances their applicability across different industries.

4. Durability Made from robust materials, Di Lug type butterfly valves are designed to withstand high pressures and temperatures, ensuring longevity and reliability. This durability translates to lower maintenance costs and reduced downtime in industrial operations.

5. Sealing Performance With advancements in seal technology, Di Lug type butterfly valves can offer excellent sealing capabilities, preventing leaks and maintaining system integrity. This is crucial in applications dealing with hazardous or valuable fluids.

Applications of Di Lug Type Butterfly Valves

The Di Lug type butterfly valve is particularly suited for applications where flow control is a priority. Common uses include

- Water Treatment In municipal water systems, these valves regulate the flow of treated water, facilitating operations in pumping stations and distribution networks. - Chemical Processing The versatility of these valves makes them suitable for controlling aggressive chemicals and ensuring safe processing in industries such as pharmaceuticals and petrochemicals. - Heating, Ventilation, and Air Conditioning (HVAC) These valves are integral in managing airflow and fluid movement within HVAC systems, contributing to energy efficiency and comfort in buildings.

Conclusion

The Di Lug type butterfly valve with a handwheel mechanism is an essential component in various industries, providing effective flow control while minimizing space requirements. Its ease of operation, durability, and versatility make it a preferred choice for many applications. As industries continue to evolve and demand more reliable valve solutions, the Di Lug type butterfly valve stands out as a robust option that ensures the smooth operation of fluid systems. Understanding its features and benefits can help stakeholders make informed decisions about fluid control solutions in their operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024