10 月 . 19, 2024 02:50 Back to list

di gate valve

Understanding Diaphragm Gate Valves Design, Function, and Applications

Diaphragm gate valves are essential components in various industrial processes, valued for their ability to provide reliable flow control while minimizing leakage. These valves operate using a flexible diaphragm, which seals against the valve seat when closed. This design not only helps ensure a tight seal but also reduces the potential for contamination, making diaphragm gate valves ideal for applications where cleanliness is paramount.

Design Features

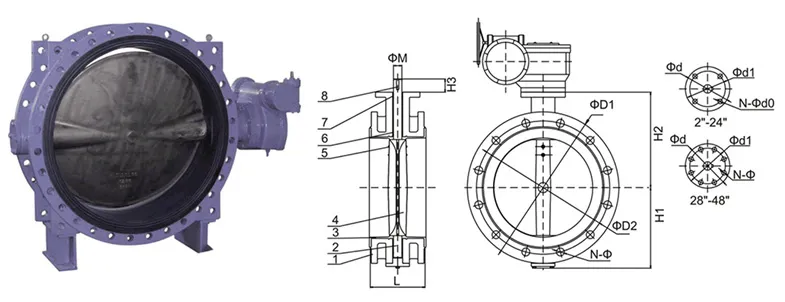

The design of a diaphragm gate valve includes several key parts the body, the diaphragm, the actuator, and the seat. The body is typically made from materials like stainless steel, PVC, or other corrosion-resistant substances, making the valve durable and suitable for harsh environments. The diaphragm is crafted from materials such as rubber or elastomers, allowing for flexibility and an effective seal. The actuator can be manual or automated, offering flexibility in operation depending on the user’s needs.

One of the standout features of diaphragm gate valves is their ability to handle varying pressures and temperatures. This versatility makes them applicable across different sectors, from water treatment facilities to pharmaceutical plants. Additionally, because the diaphragm isolates the flow from the actuator, these valves are less prone to wear and can have a longer service life compared to traditional gate valves.

di gate valve

Functionality

When the actuator is engaged, it moves the diaphragm upward, allowing fluid to pass through the valve. As the actuator is disengaged, the diaphragm returns to its original position, sealing off the flow. This simple yet effective mechanism allows for quick shut-off and precise control over fluid flow. The design minimizes the chance of leakage, which is a significant concern with many types of valves, especially in sensitive applications like chemical processing or food manufacturing.

Applications

Diaphragm gate valves find extensive applications in a variety of industries. In the water treatment sector, they play a crucial role in controlling the flow of water, ensuring proper management of resources. In the pharmaceutical industry, the tight sealing capability of diaphragm valves is vital for preventing contamination during the production of medications. Moreover, these valves are commonly used in the food and beverage industry, where hygiene is critical, and any leakage could result in contamination or product loss.

In conclusion, diaphragm gate valves are a vital part of modern industrial infrastructure. Their unique design and reliable functionality make them ideal for applications requiring precise flow control and high hygiene standards. Whether in water treatment, pharmaceuticals, or food processing, these valves contribute significantly to operational efficiency and safety. Understanding their design, functionality, and applications can aid engineers and technicians in selecting the right valve for their specific needs, ultimately enhancing the efficacy of various processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024