2 月 . 20, 2025 10:29 Back to list

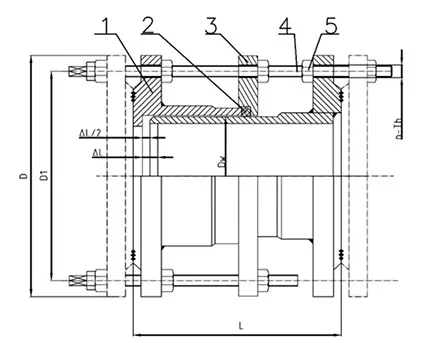

Vulcanized Seat Flange Butterfly Valve

A foot valve is an essential component that plays a crucial role in a wide range of fluid management systems worldwide. Understanding the importance of foot valves, especially the Di foot valve, can significantly enhance system efficiency and reliability.

From an expertise standpoint, selecting the correct foot valve involves understanding the specific demands of the application, including pressure ratings, flow requirements, and environmental conditions. Ductile iron foot valves excel in high-pressure environments and are rated to withstand extreme conditions, including wide temperature ranges. This adaptability ensures they meet rigorous industry standards and regulations, further cementing their position as a preferred choice for engineers and system designers. The authority of Di foot valves is further reinforced through compliance with various international standards, including ISO, ANSI, and AWWA specifications. These standards guarantee that the valves have been tested and verified through rigorous protocols to ensure optimal performance and safety. Manufacturers of Di foot valves typically hold comprehensive certifications as well, demonstrating their commitment to quality and trustworthiness in the market. The trust placed in Di foot valves is evident in their widespread adoption in critical systems globally. Many leading infrastructure projects, from water distribution networks to emergency firefighting systems, rely on these valves to maintain operational efficiency and safety. Their consistent performance has been documented across countless case studies, establishing a track record of success and fostering confidence among users and specifiers worldwide. In summary, Di foot valves offer a unique combination of strength, reliability, and efficiency pivotal for any fluid system. Their robust construction, corrosion resistance, and precise performance make them an essential component in maintaining system integrity and efficiency. Engineers and industry professionals consistently turn to ductile iron foot valves to meet their most demanding needs, supported by decades of proven performance and endorsed by stringent international standards. This blend of features ensures these valves remain a trusted choice across various applications and industries.

From an expertise standpoint, selecting the correct foot valve involves understanding the specific demands of the application, including pressure ratings, flow requirements, and environmental conditions. Ductile iron foot valves excel in high-pressure environments and are rated to withstand extreme conditions, including wide temperature ranges. This adaptability ensures they meet rigorous industry standards and regulations, further cementing their position as a preferred choice for engineers and system designers. The authority of Di foot valves is further reinforced through compliance with various international standards, including ISO, ANSI, and AWWA specifications. These standards guarantee that the valves have been tested and verified through rigorous protocols to ensure optimal performance and safety. Manufacturers of Di foot valves typically hold comprehensive certifications as well, demonstrating their commitment to quality and trustworthiness in the market. The trust placed in Di foot valves is evident in their widespread adoption in critical systems globally. Many leading infrastructure projects, from water distribution networks to emergency firefighting systems, rely on these valves to maintain operational efficiency and safety. Their consistent performance has been documented across countless case studies, establishing a track record of success and fostering confidence among users and specifiers worldwide. In summary, Di foot valves offer a unique combination of strength, reliability, and efficiency pivotal for any fluid system. Their robust construction, corrosion resistance, and precise performance make them an essential component in maintaining system integrity and efficiency. Engineers and industry professionals consistently turn to ductile iron foot valves to meet their most demanding needs, supported by decades of proven performance and endorsed by stringent international standards. This blend of features ensures these valves remain a trusted choice across various applications and industries.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024