12 月 . 03, 2024 14:28 Back to list

Understanding Dismantling Joints and Their Applications in Engineering and Construction

The Disassembly Joint An Essential Component in Modern Engineering

In the realm of modern engineering and construction, the complexity of structures and machinery often requires that components be temporarily secured or permanently affixed. However, there are instances when these components need to be disassembled for maintenance, repair, or replacement. This is where disassembly joints, often referred to as dismantling joints, come into play. These specialized connections facilitate the breakdown of assemblies without the need for complicated tools or extensive labor, ensuring efficiency and versatility in operations.

Definition and Function

Dismantling joints are mechanical connectors designed to allow for the easy and quick assembly and disassembly of components. They are used in a variety of applications, including piping systems, HVAC installations, and modular construction. The primary function of a dismantling joint is to connect two or more parts while permitting the user to easily take them apart when necessary. This is particularly useful in situations where regular maintenance is required, as it reduces downtime and labor costs.

Design Features

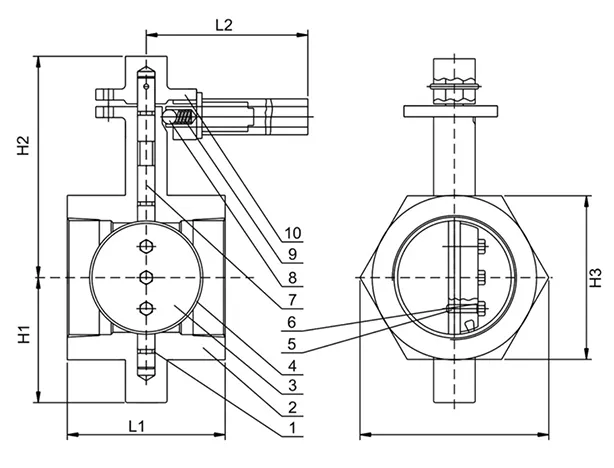

The design of dismantling joints incorporates several crucial features that enhance their functionality. Typically, they are crafted from durable materials such as stainless steel or carbon steel, ensuring they can withstand high pressures and harsh environments. Additionally, many dismantling joints include gasket seals to prevent leaks and maintain system integrity.

Moreover, dismantling joints may come with various configurations, such as flanged, threaded, or bolted designs, to suit different requirements and installation scenarios. The choice of design is often dictated by the specific application, with considerations for factors such as the type of fluid being transported, temperature variations, and environmental conditions.

Applications

di dismantling joint

Dismantling joints see extensive use across multiple industries. In plumbing and piping, for instance, they enable the easy assembly and disassembly of pipelines, allowing for straightforward maintenance and repairs without the need for cutting pipes or extensive modifications. In HVAC systems, these joints are essential for connecting ductwork, enabling technicians to access sections of the system easily for servicing.

In the realm of modular construction, dismantling joints facilitate the assembly of prefabricated components. This approach not only speeds up construction timelines but also allows for more flexible design alterations. If an adjustment is needed, dismantling joints can be easily disassembled, and components can be reconfigured, minimizing waste and resource consumption.

Advantages of Dismantling Joints

The use of dismantling joints offers several notable advantages. Firstly, they significantly reduce the time and manpower required for assembly and disassembly processes. This efficiency translates into cost savings for companies, as it allows for quicker turnaround times on projects and reduces labor costs during maintenance operations.

Secondly, dismantling joints contribute to the longevity of systems. By allowing for regular maintenance and inspections, potential issues can be identified and rectified early on, enhancing the overall reliability and lifespan of the equipment or structure.

Additionally, dismantling joints promote modularity in engineering designs. This modular approach not only streamlines construction processes but also fosters adaptability, allowing systems to evolve in response to changing needs and technologies.

Conclusion

In summary, dismantling joints play a vital role in modern engineering applications by providing a bridge between assembly and disassembly. Their efficient design and functional versatility make them essential for a wide range of industries, from plumbing and HVAC to modular construction. As technology evolves and the demand for adaptable and maintainable systems increases, the relevance of dismantling joints will continue to grow. Engineers and technicians alike must recognize the value of these components, as they not only simplify processes but also enhance the efficiency and longevity of various systems. Embracing dismantling joints in future designs will undoubtedly contribute to more sustainable and effective engineering practices.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024