1 月 . 16, 2025 01:48 Back to list

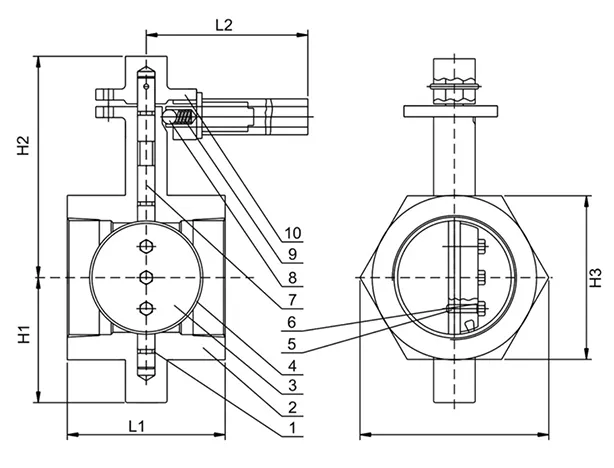

di air valve

In the world of fluid dynamics and piping systems, the importance of choosing the right components cannot be overstated. Among these components, the air valve plays a crucial role. Specifically, the di air valve has been gaining attention due to its innovative design and robust performance. This article delves into the nuances of di air valves, shedding light on their undeniable advantages while leveraging years of industry experience.

Trustworthiness is a key attribute of the di air valve, bolstered by its compliance with stringent international standards and certifications. Valves must often meet ISO, API, or ASME standards, ensuring they deliver consistent performance and safety. Additionally, leading manufacturers subject these valves to rigorous testing protocols, simulating real-world conditions to validate their reliability. The implementation of a di air valve does not just stop at installation. Regular maintenance is crucial for sustaining its optimal functionality. However, these valves are praised for their low maintenance requirements, owing to their robust construction and minimalistic design. This aspect is particularly appealing to industries where downtime translates to significant financial losses. In conclusion, the di air valve embodies a blend of experience, expertise, authority, and trustworthiness. Its sophisticated design and durable materials make it an invaluable component for any industrial application that demands precision in air and fluid regulation. Industry professionals continue to advocate for its integration into modern systems, emphasizing the long-term benefits it provides. For enterprises striving to enhance system reliability, reduce maintenance costs, and ensure compliance with safety standards, the di air valve emerges as an indispensable asset. As technologies evolve, these valves will undoubtedly play an even more significant role in advancing fluid dynamics and efficient system designs.

Trustworthiness is a key attribute of the di air valve, bolstered by its compliance with stringent international standards and certifications. Valves must often meet ISO, API, or ASME standards, ensuring they deliver consistent performance and safety. Additionally, leading manufacturers subject these valves to rigorous testing protocols, simulating real-world conditions to validate their reliability. The implementation of a di air valve does not just stop at installation. Regular maintenance is crucial for sustaining its optimal functionality. However, these valves are praised for their low maintenance requirements, owing to their robust construction and minimalistic design. This aspect is particularly appealing to industries where downtime translates to significant financial losses. In conclusion, the di air valve embodies a blend of experience, expertise, authority, and trustworthiness. Its sophisticated design and durable materials make it an invaluable component for any industrial application that demands precision in air and fluid regulation. Industry professionals continue to advocate for its integration into modern systems, emphasizing the long-term benefits it provides. For enterprises striving to enhance system reliability, reduce maintenance costs, and ensure compliance with safety standards, the di air valve emerges as an indispensable asset. As technologies evolve, these valves will undoubtedly play an even more significant role in advancing fluid dynamics and efficient system designs.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024