2 月 . 13, 2025 17:41 Back to list

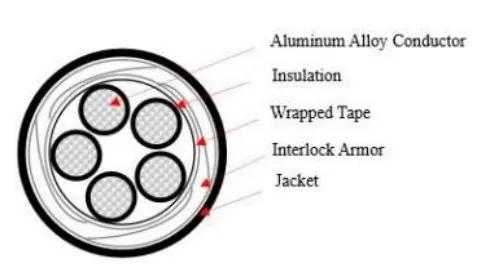

Type AC90

Control valves are an indispensable component in the realm of industrial automation, playing a crucial role in managing fluid dynamics in various processes. These devices enable users to adjust fluid flow, maintaining system stability and optimizing performance. However, the intricacies involved in selecting and maintaining them demand expertise and credibility to ensure seamless functionality.

Authoritativeness in control valve technologies is established by adhering to global standards and participating in industry certifications. Some renowned organizations like the American Society of Mechanical Engineers (ASME) and the International Society of Automation (ISA) provide guidelines that form the bedrock of valve design and deployment. Partnering with manufacturers that comply with such rigorous standards can enhance the reliability and efficiency of your control systems. Additionally, a well-documented track record of successful installations across diverse industries is a vital sign of a brand’s authority in the market. Trustworthiness is built through diligent quality assurance and aftercare services. A reliable control valve provider conducts thorough testing of their products, ensuring each unit meets stringent operational benchmarks before reaching the customer. This commitment to quality is further evidenced by comprehensive warranties and customer service that includes technical support and troubleshooting guidance. Moreover, transparency in specifications and the provision of detailed product datasheets help customers make informed decisions, augmenting trust. The investment in control valves is not limited to initial procurement; it encompasses the total lifecycle management. Effective strategies include regular maintenance checks, expert consultation for upgrades, and leveraging IoT technologies for real-time monitoring and predictive analytics. By optimizing performance and predicting failures before they occur, organizations can significantly reduce downtime and repair costs, thereby maximizing the return on investment in their control valves. Navigating the complexities of control valve systems necessitates collaboration with knowledgeable professionals who provide tailored solutions tailored to unique operational needs. The blend of experience, expertise, authoritativeness, and trustworthiness in choosing and managing control valves not only ensures operational excellence but also enhances sustainability by reducing waste and energy consumption. As industries continue to evolve, the demand for advanced control valve systems that meet emerging challenges will undoubtedly grow, reaffirming their enduring importance in industrial applications.

Authoritativeness in control valve technologies is established by adhering to global standards and participating in industry certifications. Some renowned organizations like the American Society of Mechanical Engineers (ASME) and the International Society of Automation (ISA) provide guidelines that form the bedrock of valve design and deployment. Partnering with manufacturers that comply with such rigorous standards can enhance the reliability and efficiency of your control systems. Additionally, a well-documented track record of successful installations across diverse industries is a vital sign of a brand’s authority in the market. Trustworthiness is built through diligent quality assurance and aftercare services. A reliable control valve provider conducts thorough testing of their products, ensuring each unit meets stringent operational benchmarks before reaching the customer. This commitment to quality is further evidenced by comprehensive warranties and customer service that includes technical support and troubleshooting guidance. Moreover, transparency in specifications and the provision of detailed product datasheets help customers make informed decisions, augmenting trust. The investment in control valves is not limited to initial procurement; it encompasses the total lifecycle management. Effective strategies include regular maintenance checks, expert consultation for upgrades, and leveraging IoT technologies for real-time monitoring and predictive analytics. By optimizing performance and predicting failures before they occur, organizations can significantly reduce downtime and repair costs, thereby maximizing the return on investment in their control valves. Navigating the complexities of control valve systems necessitates collaboration with knowledgeable professionals who provide tailored solutions tailored to unique operational needs. The blend of experience, expertise, authoritativeness, and trustworthiness in choosing and managing control valves not only ensures operational excellence but also enhances sustainability by reducing waste and energy consumption. As industries continue to evolve, the demand for advanced control valve systems that meet emerging challenges will undoubtedly grow, reaffirming their enduring importance in industrial applications.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024