10 月 . 06, 2024 20:09 Back to list

ci dismantling joint

The Art and Science of CI Dismantling Joints

In the realm of construction and engineering, the term CI dismantling joint refers to a vital component used in various piping systems, especially in the context of cast iron (CI) pipes. These joints are essential for facilitating the disassembly and maintenance of pipelines without causing significant disruption to the underlying infrastructure. The importance of these joints can be underscored by their application in water supply systems, wastewater treatment plants, and industrial processes where the integrity and reliability of the piping system are paramount.

Understanding CI Dismantling Joints

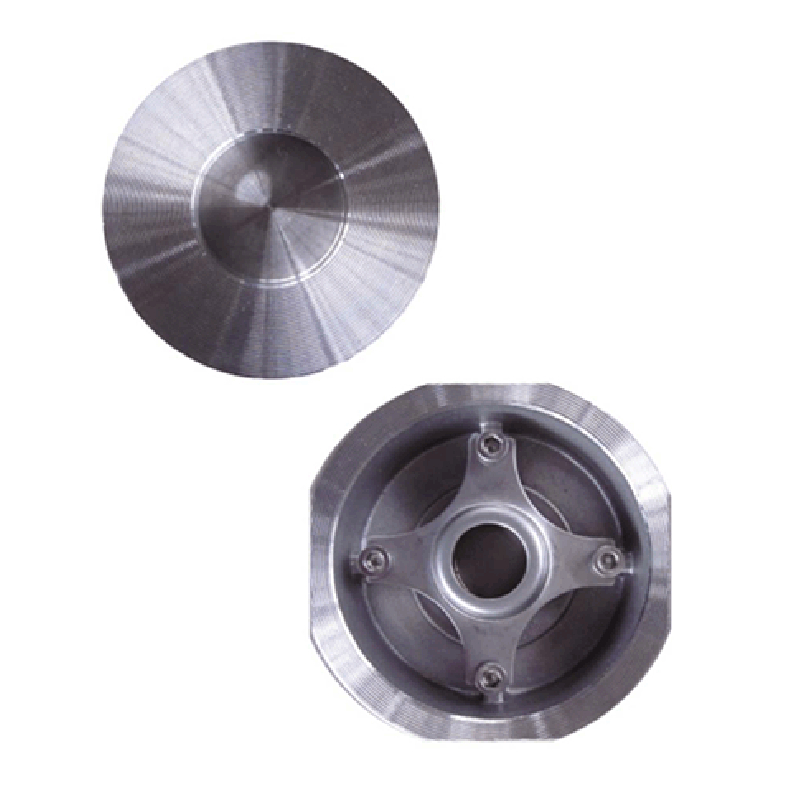

A CI dismantling joint typically consists of several components, including a body, flanges, and a mechanism that allows for controlled movement of the joints. The primary function of these joints is to provide flexible yet sturdy connections between segments of piping. They allow for easy removal of pipe sections, which is vital during maintenance, repair, or replacement tasks.

The design of a CI dismantling joint also incorporates elements that prevent stress and potential damage during installation and operation. By allowing for lateral movement, these joints minimize the risk of misalignment that can occur due to ground settlement or thermal expansion. This flexibility not only extends the lifespan of the piping system but also reduces the likelihood of leaks and other inefficiencies.

Applications and Benefits

Dismantling joints find extensive applications across various industries due to their advantageous properties. In municipal water systems, these joints enable maintenance teams to access buried pipelines without extensive excavation. This capability translates to reduced labor costs and minimized service interruptions for consumers. In wastewater treatment facilities, dismantling joints allow for routine inspections and repairs, ensuring that processes run smoothly and that environmental regulations are met.

ci dismantling joint

Another significant advantage of CI dismantling joints is their compatibility with existing piping materials. When integrating new sections into an old system, engineers can utilize these joints to maintain the integrity of the overall network. This compatibility is crucial for upgrading infrastructures in urban environments where existing systems may be decades old.

Installation and Maintenance

The installation of CI dismantling joints requires careful planning and execution to ensure they function optimally. The height, size, and alignment must all be addressed during the installation to prevent future issues. Proper training for personnel is essential to mitigate errors during installation, which could lead to leaks or system failures.

Additionally, maintenance plays a critical role in prolonging the life of these components. Regular inspections can identify components that may be wearing out or are at risk of failing. By addressing issues proactively, facilities can reduce the likelihood of unplanned outages and costly repairs.

Conclusion

In conclusion, CI dismantling joints are indispensable elements of modern piping systems, combining functionality with efficiency. Their ability to adapt to various conditions while providing ease of maintenance makes them a preferred choice in both new installations and retrofitting projects. As urbanization continues to expand and existing infrastructure ages, the importance of these joints will only grow, reinforcing their role in ensuring the reliability and effectiveness of piping systems across diverse applications. Investing in the proper use and maintenance of dismantling joints is essential for sustaining the infrastructure that supports our daily lives.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024