10 月 . 13, 2024 01:37 Back to list

check valve with counterweight

Understanding Check Valves with Counterweights

Check valves are essential components in various fluid systems, ensuring the unidirectional flow of liquids and gases. Among the myriad of designs available, check valves with counterweights offer unique advantages, enhancing functionality and performance in specific industrial applications. This article will explore the workings, benefits, and applications of check valves with counterweights.

What is a Check Valve with Counterweight?

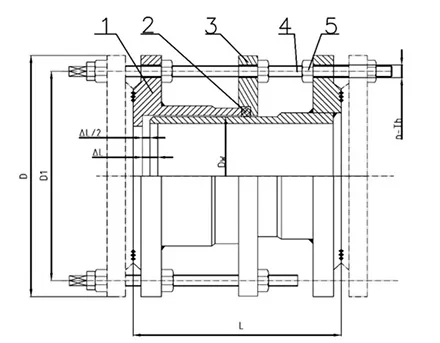

A check valve is a valve that typically allows fluid to flow in one direction while preventing backflow. This is crucial in systems where backflow could cause operational failures or contamination. The addition of a counterweight aids in the valve's operation by helping to close the valve more swiftly when needed.

In a traditional check valve, the closure mechanism relies primarily on the back pressure of the fluid. However, when utilizing a counterweight, the design incorporates a weighted closure element that assists in quickly sealing the valve, reducing the time taken to prevent backflow. This makes check valves with counterweights particularly beneficial in dynamic systems where flow rates can fluctuate significantly.

Benefits of Using Check Valves with Counterweights

1. Improved Performance The counterweight mechanism allows the valve to respond quickly to changes in flow direction. This rapid response minimizes the risk of backflow, which is crucial in applications such as water treatment plants, pumping stations, and various petrochemical processes.

2. Energy Efficiency By enhancing the closing speed of the valve, counterweighted check valves can reduce energy loss associated with unwanted backflow. This can lead to lower operational costs and improved efficiency in fluid systems.

check valve with counterweight

3. Reduced Noise and Vibration In systems where conventional check valves struggle with slamming and chattering (noisy behaviors when the valve closes), counterweighted designs can minimize these issues. The gradual offset of weight helps to cushion the closure, resulting in a quieter operation.

4. Versatility Check valves with counterweights can be custom-designed to suit specific applications, making them suitable for various industries ranging from wastewater management to manufacturing facilities.

5. Durability The robust nature of these valves, combined with the counterweight feature, tends to enhance durability as they can withstand more sudden pressures without being damaged or wearing out quickly.

Applications in Various Industries

Check valves with counterweights are widely used across different sectors. In the water and wastewater treatment sector, these valves prevent contaminated water from flowing back into clean systems, maintaining water quality and safety. In the oil and gas industry, they play a crucial role in managing fluid flows, ensuring that pipelines operate safely and efficiently. Additionally, in HVAC systems, counterweighted check valves help to regulate the flow of air and fluids, improving system reliability and performance.

Conclusion

Check valves with counterweights represent a significant advancement in fluid control technology, bridging the gap between conventional designs and the need for efficient, responsive operation in dynamic environments. As industries continue to evolve and the demand for reliable fluid systems increases, the role of these innovative check valves will undoubtedly grow. Engineers and system designers must consider the benefits offered by counterweighted check valves to enhance their systems' efficiency, durability, and overall performance. By integrating this technology, industries can better prepare for the challenges of modern fluid management, ensuring safe and consistent operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024