10 月 . 09, 2024 05:46 Back to list

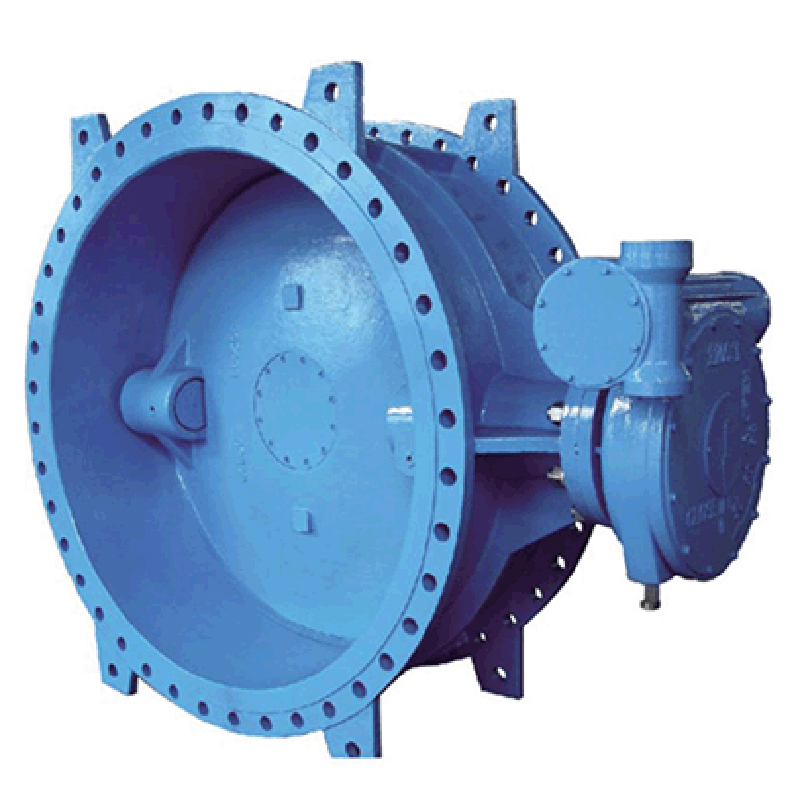

Counterweighted Check Valve for Enhanced Performance and Reliability

Check Valve with Counterweight An Innovative Solution for Fluid Control

In the realm of fluid control systems, check valves play a crucial role in preventing backflow, ensuring that fluids only move in one direction

. Among the various types of check valves, those equipped with counterweights have emerged as a remarkable innovation, offering enhanced performance and efficiency in fluid management.A check valve, fundamentally, is a mechanical device designed to allow fluid to flow through it in one direction while preventing reverse flow. This is vital in systems where back pressure could lead to leakage or contamination. Traditional check valves utilize spring mechanisms to accomplish this task; however, incorporating a counterweight provides distinct advantages that improve their functionality and reliability.

The inclusion of a counterweight in a check valve introduces a dynamic system that counters the weight of the fluid. When the fluid moves in the intended direction, the counterweight assists the valve in opening more smoothly and efficiently. Conversely, if there is a tendency for backflow, the counterweight aids in quickly closing the valve, minimizing the risk of reverse flow and potential system damage. This mechanism enhances the overall responsiveness of the valve, contributing to safer and more effective fluid control in various applications.

check valve with counterweight

One of the primary benefits of using check valves with counterweights is their ability to operate effectively in challenging conditions. For instance, in systems where fluid dynamics can lead to fluctuating pressures, these valves can adapt more readily. Their design allows for quicker response times, which is essential in preventing abrupt changes that might otherwise compromise system integrity. This adaptability makes them ideal for industries such as water treatment, oil and gas, and chemical processing, where maintaining continuous flow and preventing contamination are paramount.

Moreover, check valves with counterweights often exhibit reduced wear and tear compared to their spring-based counterparts. The softer closing action facilitated by the counterweight decreases the impact of hydraulic shock, extending the lifespan of the valve and reducing the frequency of maintenance interventions. This characteristic not only enhances the reliability of the system but also results in cost savings over time, as facilities can operate without the constant need for valve replacements or repairs.

When considering installation, check valves with counterweights can be implemented in various orientations, making them versatile for different setups. This flexibility allows engineers to design systems tailored to specific operational requirements without being constrained by the limitations of traditional valve mechanisms.

In conclusion, check valves with counterweights represent a significant advancement in fluid control technology. Their ability to provide smooth operation, rapid response to pressure changes, and enhanced durability makes them an attractive option for many industrial applications. As industries continue to seek improvements in efficiency and safety, the adoption of these innovative valves will likely increase, setting a new standard for fluid management solutions. As technology evolves, the exploration of check valves with counterweights promises to unlock even greater potential in optimizing fluid systems worldwide.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024