11 月 . 01, 2024 00:06 Back to list

Leading Manufacturers of High-Quality Check Valves for Diverse Applications

Understanding Check Valve Manufacturers A Key Component in Fluid Dynamics

Check valves are essential components in various fluid systems, ensuring the unidirectional flow of liquids and gases while preventing backflow. Manufacturers of check valves play a crucial role in a wide range of industries, from oil and gas to water treatment and beyond. Understanding the landscape of check valve manufacturers can help businesses choose the right components for their specific applications.

Check valves come in various designs, including swing check valves, ball check valves, and diaphragm check valves. Each type has its own advantages and is suited to different operational requirements. For instance, swing check valves utilize a disc that swings on a hinge, allowing fluid to flow in one direction and preventing backflow. This design is typically used in larger pipe systems and is favored for its ability to handle high flow rates and pressures.

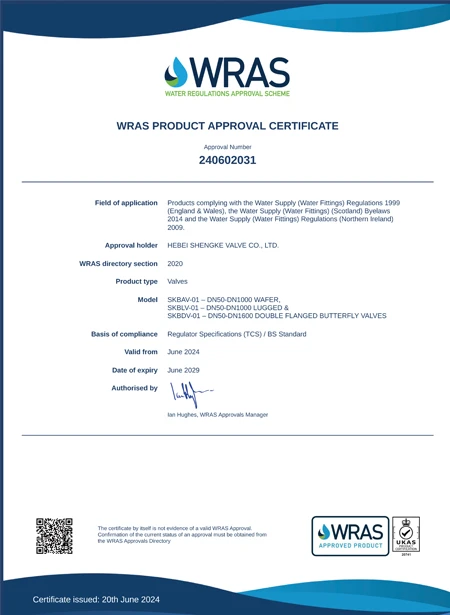

When selecting a check valve manufacturer, several factors should be considered. Quality assurance is paramount; reputable manufacturers adhere to stringent industry standards such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI). Compliance with these standards ensures that the valves are tested for durability, reliability, and performance, providing peace of mind to end-users.

check valve manufacturers

Another important aspect is the manufacturing materials used. Check valves can be made from various materials, including bronze, stainless steel, PVC, and more, each offering different benefits in terms of corrosion resistance, temperature tolerance, and pressure handling capabilities. Leading manufacturers often provide detailed specifications and material certifications, allowing customers to choose the right valve based on their operational environment.

Moreover, it’s essential for manufacturers to have a solid reputation in the marketplace. Customer reviews, industry certifications, and case studies can all provide insight into a manufacturer’s reliability and product performance. Many established check valve manufacturers also offer customization options, allowing businesses to request specific sizes, designs, or materials tailored to their unique needs.

Lastly, customer support and after-sales service are pivotal. A responsive manufacturer can provide valuable assistance in installation, maintenance, and troubleshooting, ensuring that their check valves operate efficiently throughout their lifespan.

In summary, the choice of check valve manufacturer can significantly influence the overall performance and reliability of fluid systems. By focusing on quality, materials, reputation, and customer service, businesses can make informed decisions that enhance their operational efficiency and safety. Investing time in understanding and selecting the right check valve manufacturer ultimately pays off in the long run, contributing to smoother and more efficient fluid dynamics in various applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024