10 月 . 01, 2024 01:07 Back to list

Exploring the Benefits and Applications of Cast Iron Valves in Industrial Settings

Understanding Cast Iron Valves Strength, Durability, and Applications

Cast iron valves are essential components in various industrial and municipal applications, providing robust and reliable control over the flow of liquids and gases. Known for their durability and ability to withstand high pressures and temperatures, these valves are crafted from cast iron, a material that has been utilized for centuries due to its favorable properties. In this article, we delve into the characteristics, types, advantages, and applications of cast iron valves, highlighting their importance in modern infrastructure.

What is Cast Iron?

Cast iron is an iron-carbon alloy with a carbon content greater than 2%. It is distinguished by its excellent castability, high wear resistance, and good machinability. The production process involves melting scrap iron, along with other alloying elements, and pouring it into molds. Once solidified, the cast iron can be machined to achieve precise shapes and dimensions. The unique structure of cast iron, characterized by its crystalline microstructure, contributes to its strength and resilience.

Types of Cast Iron Valves

There are several types of cast iron valves, including

1. Gate Valves Often used in on/off applications, gate valves provide minimal resistance to flow when fully opened, making them suitable for regulating flow in pipelines.

2. Globe Valves These valves are designed for throttling flow and provide better flow regulation compared to gate valves. The linear motion of the valve disc allows for precise adjustments.

3. Check Valves Preventing backflow is crucial in many systems. Cast iron check valves automatically allow flow in one direction and close when the flow reverses, protecting equipment and maintaining system integrity.

4. Ball Valves Known for their quick operation and reliability, ball valves feature a spherical disc that controls flow. They are often preferred in applications requiring tight shut-off.

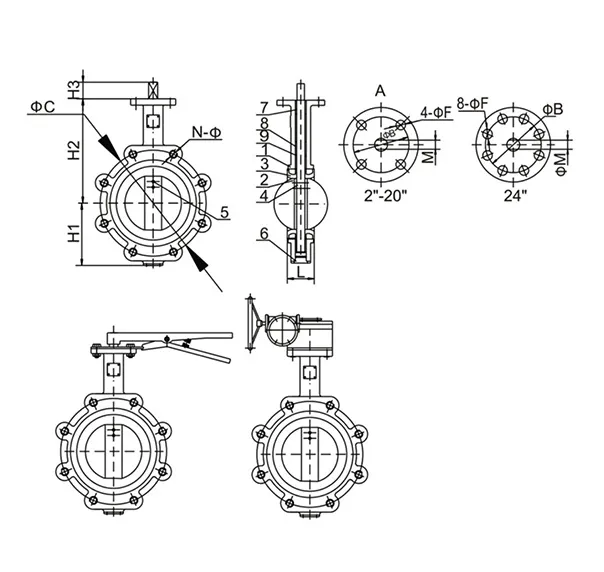

5. Butterfly Valves These valves use a rotating disc to regulate flow and are particularly useful in applications where space is limited.

Advantages of Cast Iron Valves

1. Durability Cast iron valves can withstand harsh conditions, including extreme temperatures and corrosive environments, making them ideal for use in water treatment facilities, chemical plants, and power stations.

cast iron valve

2. Cost-Effectiveness While initial costs may be higher than alternative materials, the longevity and low maintenance requirements of cast iron valves lead to significant savings over time.

3. Versatility Cast iron valves can be manufactured in various sizes and styles to accommodate different pressure ratings and flow requirements. Their adaptability makes them suitable for a wide range of applications.

4. High Strength Cast iron is renowned for its high tensile strength, which allows valves to operate effectively under pressures that might compromise other materials.

Applications of Cast Iron Valves

Cast iron valves find extensive applications across numerous industries. Some common uses include

- Water Supply Systems Cast iron valves are widely used in municipal water distribution systems to ensure reliable flow control and prevent backflow. - Wastewater Treatment In sewage treatment plants, these valves help manage the flow of wastewater, contributing to effective treatment processes.

- Chemical Processing The resilience of cast iron against corrosive substances makes these valves suitable for various chemical applications.

- Power Generation In power plants, cast iron valves are utilized to manage steam, water, and other fluids, ensuring the efficient operation of machinery.

- Fire Protection Systems Fire sprinkler systems often incorporate cast iron valves to ensure reliable and effective water flow during emergencies.

Conclusion

Cast iron valves stand out for their strength, durability, and cost-effectiveness, making them a preferred choice in a variety of applications. Their ability to withstand harsh conditions and provide reliable performance has established them as a crucial component in many industrial and municipal systems. As industries continue to seek efficient solutions for fluid control, cast iron valves will remain a vital part of the infrastructure landscape for years to come.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024