10 月 . 15, 2024 11:40 Back to list

Durable Cast Iron Butterfly Valve for Efficient Flow Control in Various Applications

The Cast Iron Butterfly Valve An Overview

Butterfly valves are essential components in various industries, providing efficient flow regulation in piping systems. Among the many materials used for their construction, cast iron remains a popular choice due to its robust properties and cost-effectiveness. In this article, we will explore the features, advantages, and applications of cast iron butterfly valves, highlighting why they are esteemed in industrial applications.

What is a Butterfly Valve?

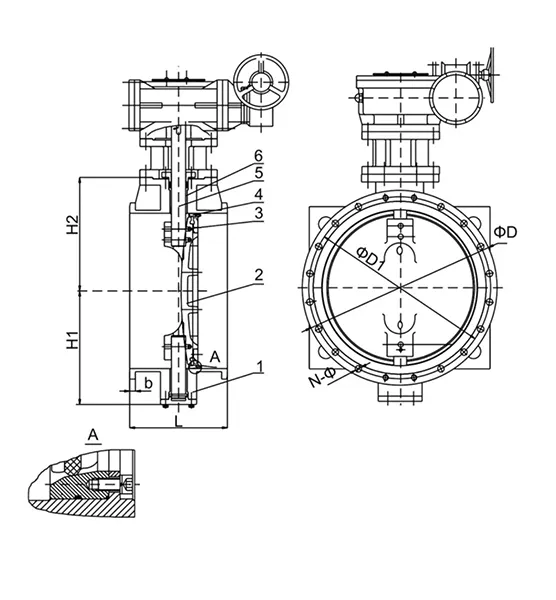

A butterfly valve is a quarter-turn rotational valve that uses a circular disc or butterfly to regulate flow. The disc is mounted on a shaft that passes through the center, allowing it to rotate either parallel or perpendicular to the flow direction. When rotated, the disc opens or closes the passage, effectively controlling the fluid flow. Due to their simple design, butterfly valves offer an excellent sealing capability and can handle a wide range of fluid types.

Cast Iron as a Material Choice

Cast iron is an iron-carbon alloy with a higher carbon content than wrought iron. Its cast composition grants it several desirable characteristics. The material is known for its excellent wear resistance, strength, and ability to withstand high temperatures. Additionally, cast iron is relatively inexpensive compared to other materials, making it a cost-effective solution for many industrial applications.

Advantages of Cast Iron Butterfly Valves

1. Durability Cast iron butterfly valves are highly durable and can withstand harsh operating conditions. They exhibit excellent resistance to corrosion, especially when coated or painted to prevent rusting. This durability extends the valve's lifespan, reducing the frequency of replacement or maintenance.

2. Cost-Effectiveness The manufacture of cast iron butterfly valves is economical, making them a popular choice for projects with budget constraints. The initial investment in cast iron valves often yields long-term savings due to their low maintenance requirements and extended operational life.

3. Versatility Cast iron butterfly valves are suitable for managing various fluids, including liquids, gases, and slurries. Their design allows them to function effectively in a range of temperatures and pressures, making them versatile in their applications.

4. Space Efficiency The compact design of butterfly valves means they require less space than other types of valves. This is particularly beneficial in installations where space is limited. The lightweight nature of cast iron butterfly valves also simplifies installation and reduces support structure requirements.

cast iron butterfly valve

5. Easy Operation Butterfly valves are easy to operate, whether manually or through automation. Their quarter-turn operation allows for quick opening and closing, enabling precise flow control with minimal effort.

Applications of Cast Iron Butterfly Valves

Cast iron butterfly valves find use in numerous industries due to their versatility and durability. Some common applications include

- Water Treatment In water treatment facilities, these valves control the flow of water and various chemicals used in the purification process. Their resistance to corrosion makes them ideal for handling aggressive fluids.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, cast iron butterfly valves regulate airflow and help maintain desired temperatures within building environments.

- Chemical Processing The chemical industry often relies on cast iron valves due to their ability to withstand corrosive substances, making them suitable for managing various chemicals in processing plants.

- Food and Beverage In the food processing industry, cast iron butterfly valves can manage the flow of liquid ingredients while adhering to hygiene standards, especially when properly coated.

- Mining and Mineral Processing These valves are used in mining operations to handle slurries and other abrasive materials, where toughness and resistance to wear are crucial.

Conclusion

Cast iron butterfly valves are a cornerstone in the realm of fluid control equipment. Offering a combination of durability, cost-effectiveness, and versatility, they are well-suited for a wide range of applications spanning various industries. As industries continue to evolve and demand reliable and efficient flow regulation solutions, cast iron butterfly valves will undoubtedly remain a vital component of piping systems worldwide. Through understanding their features and applications, engineers and operators can make informed decisions when selecting the right components for their fluid management needs.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024