9 月 . 30, 2024 04:30 Back to list

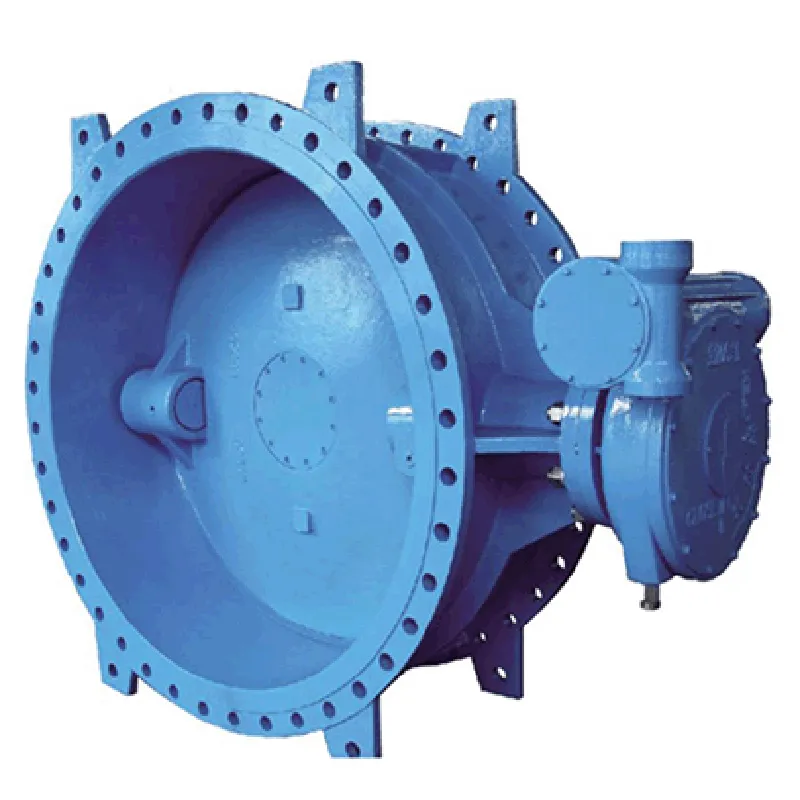

Durable Cast Iron Air Valve for Enhanced Performance and Reliability in Various Applications

The Significance of Cast Iron Air Valves in Modern Industry

Cast iron air valves play a crucial role in various industrial applications, providing essential functions in controlling and regulating airflow in systems ranging from HVAC (Heating, Ventilation, and Air Conditioning) systems to pneumatic machinery in factories. The durability, strength, and corrosion resistance of cast iron make it an excellent material choice for these critical components. In this article, we will delve into the features, advantages, applications, and maintenance of cast iron air valves, highlighting their importance in modern industry.

Understanding Cast Iron Air Valves

Air valves are devices designed to regulate the flow of air into and out of a system. In numerous industrial settings, these valves need to withstand high levels of stress and diverse environmental conditions. Cast iron, known for its robustness and ability to handle extreme pressures and temperatures, serves as an ideal material for manufacturing these valves.

Cast iron air valves typically feature a simple yet effective design consisting of a body, bonnet, and actuator. They can be classified into several types, including pressure relief valves, check valves, and control valves, each serving specific functions within air management systems.

Advantages of Cast Iron Air Valves

1. Durability Cast iron is renowned for its toughness and ability to withstand wear and tear. This durability ensures a long service life for air valves, reducing the need for frequent replacements.

2. Corrosion Resistance The inherent properties of cast iron provide a certain level of resistance against corrosion, making these valves suitable for various environmental conditions, including humid atmospheres or applications where exposure to chemicals is likely.

3. Cost-Effectiveness Due to their long lifespan and lower maintenance requirements, cast iron air valves prove to be cost-effective solutions in the long run, despite a potentially higher initial investment compared to other materials.

4. Heat Resistance Cast iron can tolerate high temperatures, an essential feature in many industrial processes, ensuring that the valves maintain functionality even in extreme conditions.

5. Performance Reliability With a well-designed cast iron air valve, industries can expect consistent performance and reliable operation, reducing downtime and enhancing productivity.

Applications of Cast Iron Air Valves

The applications of cast iron air valves are diverse

. They are commonly used incast iron air valve

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves regulate airflow to ensure optimal climate control, improving energy efficiency in residential and commercial buildings.

- Manufacturing In factories where pneumatic systems are prevalent, cast iron air valves help control the flow of compressed air, critical for operating machinery, tools, and equipment.

- Water Supply Cast iron air valves are utilized in water supply systems to manage the release of built-up air, preventing pressure-related issues and ensuring smooth operation.

- Industrial Boilers In energy generation plants, these valves play a role in managing airflow for combustion processes, enhancing efficiency and safety.

Maintenance of Cast Iron Air Valves

Regular maintenance of cast iron air valves is essential to ensure longevity and efficient operation. Here are some key practices

- Routine Inspection Regularly check for leaks, corrosion, or any signs of wear. Early detection of problems can prevent costly repairs down the line.

- Lubrication Ensure that moving parts are well-lubricated to prevent sticking and wear, promoting smooth operation.

- Cleaning Dirt and debris can obstruct valve operation. Regular cleaning will help maintain functionality.

- Replace Seals Over time, seals may degrade, leading to air leaks. Replacing them as needed is crucial for maintenance.

Conclusion

Cast iron air valves are indispensable components in various industrial applications, including HVAC systems, manufacturing processes, and water management. Their durability, corrosion resistance, and heat tolerance make them a preferred choice in situations where performance is non-negotiable. As industries continue to evolve, the role of cast iron air valves will remain significant, ensuring that air management systems operate efficiently and reliably, contributing to productivity and sustainability in modern industry.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024