10 月 . 10, 2024 13:39 Back to list

casting ball valve

The Role of Casting Ball Valves in Modern Industrial Applications

In the realm of fluid control systems, ball valves have established themselves as essential components for various industries, including oil and gas, chemical processing, and water treatment. Among the various manufacturing methods for these critical valves, casting remains one of the most prominent techniques. Casting ball valves not only provide reliability and durability but also showcase remarkable engineering innovation in their design and application.

Understanding Casting Ball Valves

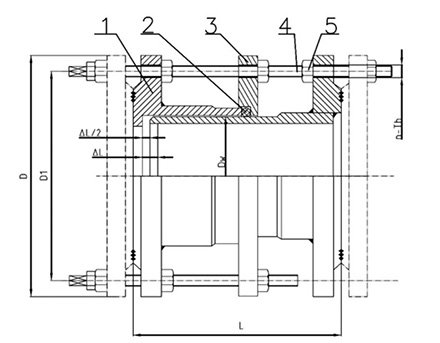

Casting ball valves are designed utilizing a process in which molten metal is poured into a mold to create the valve body. This process allows for the production of complex shapes and sizes, ensuring that the valve can meet specific operational requirements. The primary component of a ball valve is the spherical disc, or ball, which controls the flow of fluid through the valve. When the ball is rotated 90 degrees, it either opens or closes the flow passage, effectively regulating the fluid flow with minimal resistance.

One of the significant advantages of casting ball valves is their robust construction. The casting process allows manufacturers to produce valves from various materials, including stainless steel, cast iron, and brass, which are resistant to corrosion, high pressure, and high temperatures. As a result, casting ball valves can serve in demanding environments, making them ideal for handling aggressive fluids and gases in severe service applications.

Design and Functionality

Casting ball valves come in various designs, including floating ball and trunnion-mounted ball configurations. Floating ball valves feature a ball that moves freely within the valve body, relying on the pressure of the incoming fluid to keep the ball sealed against the seat. On the other hand, trunnion-mounted ball valves have a fixed ball that is held in place by a trunnion bearing, allowing for greater stability and reduced seat wear under high pressure or high flow conditions.

casting ball valve

The sealing mechanisms of casting ball valves are crucial for their performance

. Typically, these valves employ resilient materials such as PTFE (Polytetrafluoroethylene) for the seats and seals, allowing for tight sealing and long service life. Additionally, many casting ball valves come equipped with features like blow-out-proof stems, manual operators, or actuators, enhancing their usability in various applications.Applications of Casting Ball Valves

The versatility of casting ball valves has led to their widespread use across multiple sectors. In the oil and gas industry, they are utilized in upstream, midstream, and downstream processes, managing the flow of crude oil, natural gas, and various chemical products. In chemical processing plants, casting ball valves are essential for controlling corrosive substances while maintaining safety and efficiency. Moreover, in water treatment facilities, they play a vital role in regulating water flow and maintaining system pressure.

The energy sector also benefits significantly from casting ball valves, especially in renewable energy applications like geothermal and solar thermal power plants. These valves help manage the flow of geothermal fluids or thermal transfer fluids, ensuring efficient energy production and system reliability.

Conclusion

Casting ball valves represent a vital component of modern fluid control systems, combining durability, versatility, and efficiency. Their innovative design and robust materials enable them to perform excellently across various industries, making them indispensable in today’s industrial landscape. As technology advances and industries evolve, the significance of casting ball valves will continue to grow, highlighting their role in ensuring the safe and efficient operation of fluid management systems around the globe. Industries looking for reliable solutions in fluid control should consider investing in high-quality casting ball valves to meet their operational needs and improve overall efficiency.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024