8 月 . 30, 2024 19:28 Back to list

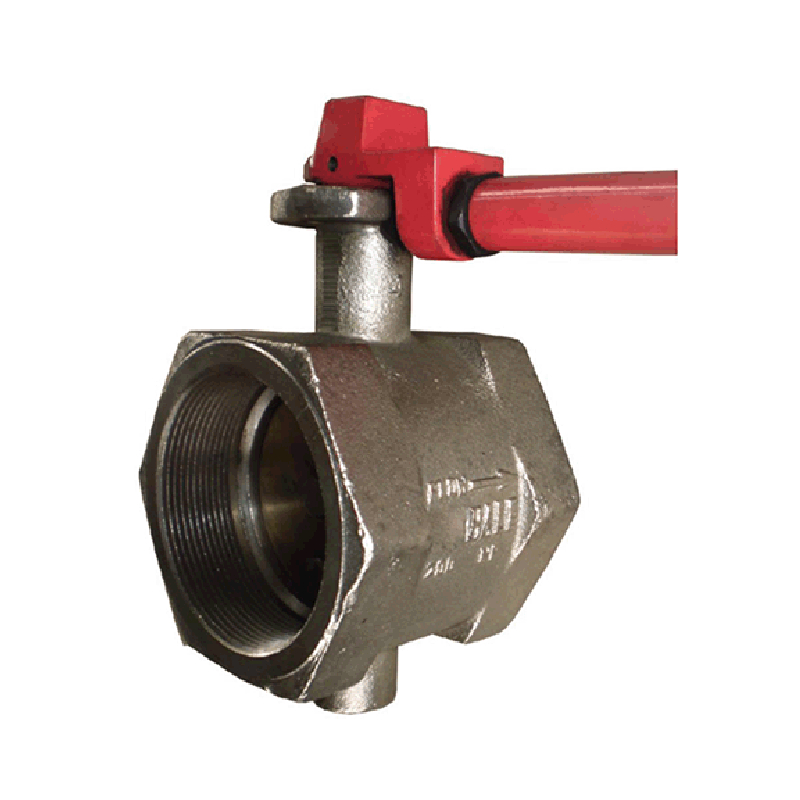

cast steel valve

Cast Steel Valves A Comprehensive Overview

Cast steel valves play a critical role in various industrial applications, including oil and gas, water treatment, power generation, and chemical processing. Renowned for their robust construction and reliability, these valves serve as vital components in the control and regulation of fluid flows. In this article, we will delve into the key characteristics, benefits, and applications of cast steel valves.

At the heart of cast steel valves is their manufacturing process. Cast steel is produced by melting iron and alloying it with carbon and other elements, resulting in a material that possesses high tensile strength and durability. This makes cast steel valves particularly suitable for high-pressure and high-temperature environments, where other materials may fail. Moreover, the casting process allows for more intricate designs compared to other manufacturing methods, enabling engineers to create custom solutions tailored to specific system requirements.

One of the primary advantages of cast steel valves is their exceptional resistance to corrosion and wear. Many industries operate under challenging conditions that can lead to premature failure of components. Cast steel valves, especially those treated with protective coatings, are able to withstand corrosive substances and abrasive materials, extending their operational lifespan. Furthermore, the solidity of cast steel contributes to a lower risk of leakages, which is critical in ensuring safety and efficiency in industrial operations.

cast steel valve

Another significant benefit of cast steel valves is their versatility. They can be designed in various configurations such as gate, globe, ball, and check valves, each serving different functions. For instance, gate valves are excellent for on/off control, while globe valves are preferred for throttling flow. This versatility allows for a wide range of applications across diverse industries. Cast steel valves are capable of handling a variety of fluids, including water, oils, and gases, thereby making them integral components in many systems.

In terms of installation and maintenance, cast steel valves offer practical advantages. Their robust design generally requires less frequent replacement, leading to lower long-term maintenance costs. Additionally, many cast steel valves come with standard connections that simplify installation processes. This ease of integration into existing systems is invaluable for industries aiming to enhance operational efficiency without extensive downtime.

With the increasing demand for reliable and efficient fluid control systems, the market for cast steel valves continues to expand. Manufacturers are focusing on innovation, producing valves that not only adhere to stringent international standards but also incorporate advanced technologies for better performance. This evolution includes the development of automated valves equipped with sensors and control systems that facilitate remote monitoring and operation, enhancing overall system efficiency.

In conclusion, cast steel valves are indispensable components in today’s industrial landscape. Their robustness, versatility, and efficiency make them an ideal choice for applications where durability and reliability are paramount. As industries evolve and the need for sophisticated fluid management systems increases, cast steel valves will undoubtedly remain at the forefront, ensuring that operations run smoothly and safely. Investing in high-quality cast steel valves is not just a matter of meeting current operational needs; it's also a strategic move towards long-term sustainability and efficiency in various sectors.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024