9 月 . 03, 2024 09:07 Back to list

cast steel valve

The Importance of Cast Steel Valves in Industrial Applications

Cast steel valves play a crucial role in various industrial applications, serving as vital components in systems that control the flow of fluids and gases. Known for their robustness and durability, these valves are essential in sectors such as oil and gas, water treatment, chemical processing, and power generation.

One of the primary advantages of cast steel valves is their strength. Made from high-quality steel alloys, these valves can withstand high pressures and temperatures, making them suitable for extreme operating conditions. This durability is particularly important in industries where equipment is subjected to harsh environments, such as offshore drilling or power plants.

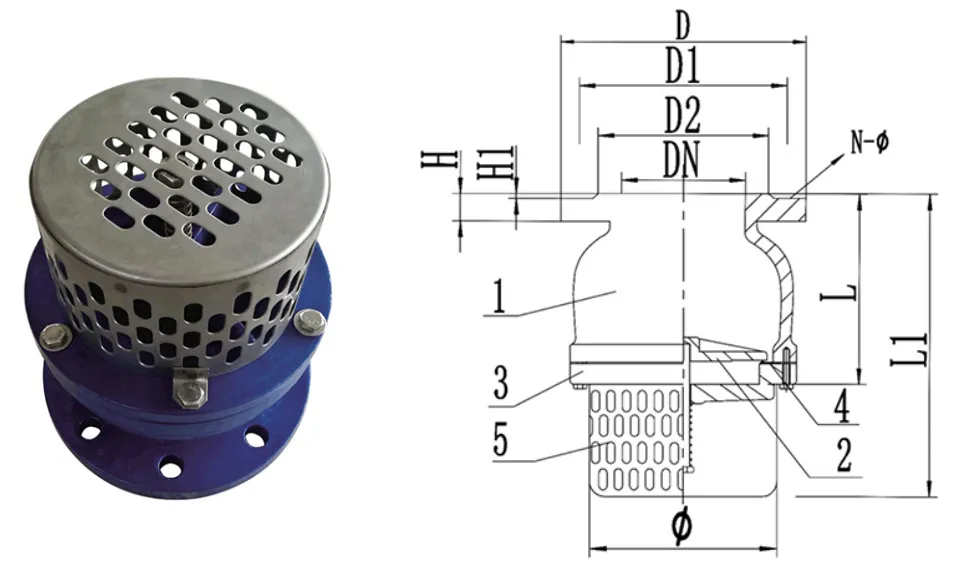

Another significant benefit of cast steel valves is their versatility. They are available in a wide range of designs, including gate, globe, ball, and check valves, each tailored for specific applications. For instance, gate valves are typically used for on/off control, whereas globe valves are favored for throttling flow. This variety ensures that engineers can select the most appropriate valve type for their specific needs, enhancing overall system efficiency.

cast steel valve

Furthermore, cast steel valves offer excellent sealing capabilities, which helps prevent leaks and reduces maintenance costs. The precision engineering involved in their manufacture allows for tight seals between the valve and piping, significantly lower the risk of fluid loss. This is particularly advantageous in industries where safety and environmental concerns are paramount.

In terms of longevity, cast steel valves are an excellent investment. Their resistance to corrosion and erosion, especially when treated with protective coatings, ensures a longer service life compared to valves made from less durable materials. This longevity not only reduces replacement costs but also minimizes system downtime, contributing to overall operational efficiency.

Moreover, advancements in technology have led to improved designs and manufacturing processes for cast steel valves. Innovations such as computer-aided design (CAD) allow for more precise and optimized valve shapes, enhancing flow characteristics and performance. As industries increasingly adopt automation and smart technologies, integrating these advanced valves into systems will become even more prevalent.

In conclusion, cast steel valves are indispensable in modern industrial settings. Their strength, versatility, reliability, and long service life make them a preferred choice for engineers and operators alike. As industries continue to evolve and face new challenges, the role of cast steel valves in ensuring safe and efficient operation will remain vital. Investing in high-quality cast steel valves is not just a matter of compliance; it is a commitment to operational excellence and sustainability.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024