9 月 . 15, 2024 15:32 Back to list

cast steel check valve

The Importance of Cast Steel Check Valves in Industrial Applications

Cast steel check valves are essential components in various industrial applications, designed to allow fluid flow in one direction while preventing backflow. These valves play a critical role in maintaining system integrity and optimizing operational efficiency in sectors such as oil and gas, water treatment, power generation, and food processing.

Design and Materials

Cast steel check valves are typically manufactured from carbon steel or alloy steel, chosen for their excellent strength, durability, and resistance to high pressure and temperature. The casting process allows for intricate designs that cater to specific application requirements. With a robust end connection, cast steel check valves are capable of withstanding vigorous operational conditions, making them a preferred choice for heavy-duty applications.

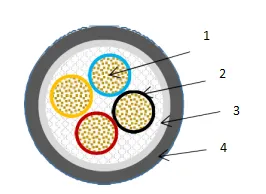

The design includes components such as the body, disc, and seat, which are engineered to minimize turbulence and pressure drops across the valve. Various types of check valves exist, including swing, lift, and ball types, each suited for different operational needs. For example, swing check valves, which utilize a hinged disc mechanism, are commonly used in applications with a relatively low velocity fluid flow, while lift check valves are ideal for high-velocity flows.

Operational Benefits

One of the significant advantages of cast steel check valves is their ability to prevent backflow, thereby protecting pumps, compressors, and other system components from damage

. This function is crucial in preventing the contamination of fluids and maintaining the efficiency of processes, particularly in industries handling hazardous materials.cast steel check valve

Moreover, cast steel check valves are designed to operate automatically without the need for manual intervention. This feature enhances operational reliability and minimizes the chances of human error. They can quickly respond to changes in flow conditions, ensuring that the fluid flows in the intended direction at all times.

Installation and Maintenance

Installation of cast steel check valves is relatively straightforward, but it requires a clear understanding of the system's flow direction and pressure ratings. Proper installation is vital to ensure optimal performance and longevity. They can be installed in both vertical and horizontal pipelines, although horizontal installation is more common.

Routine maintenance is essential for maximizing the lifespan of these valves. Regular inspections can help in identifying wear and tear and potential leak points. Although cast steel valves are designed for robust performance, environmental factors such as corrosive substances, extreme temperatures, and mechanical stresses can lead to deterioration over time. Thus, implementing a preventive maintenance schedule is crucial for ensuring ongoing efficiency.

Conclusion

In conclusion, cast steel check valves are a vital component in many industrial systems, providing reliability and safety by ensuring unidirectional flow and preventing backflow. Their design and material properties make them suitable for demanding environments where durability and resistance to pressure are paramount. Understanding their operational mechanisms and implementing proper maintenance can significantly enhance the efficiency and longevity of industrial applications. Consequently, investing in quality cast steel check valves is essential for any operation that prioritizes safety, efficiency, and reliability in fluid management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024