9 月 . 08, 2024 01:50 Back to list

High-Quality Cast Steel Check Valves for Reliable Fluid Control

Cast Steel Check Valves An Overview

Cast steel check valves play a crucial role in various industrial applications, ensuring flow control and system integrity. These valves are designed to allow fluid to flow in one direction while preventing backflow, thus safeguarding pipelines and equipment from potential damage. The importance of cast steel check valves cannot be overstated, as they are integral to the efficient and safe operation of many systems in sectors such as oil and gas, water treatment, and chemical processing.

What Are Cast Steel Check Valves?

Cast steel check valves are made from cast steel, a material known for its durability, strength, and resistance to deformation. These valves are typically used in high-pressure applications, where robust construction is essential to withstand the stress of flowing fluids and harsh operating conditions. The term check valve refers to a specific design that incorporates a disc or ball mechanism, which opens to allow fluid to pass through and closes to prevent reverse flow.

Key Features and Benefits

One of the primary advantages of cast steel check valves is their exceptional strength and resilience. Cast steel provides a higher tensile and yield strength compared to other materials, such as brass or plastic, making these valves suitable for demanding environments. Additionally, they can handle a wide range of temperatures and pressures, making them versatile components in various industrial processes.

Another benefit is their reliable operation. The design of cast steel check valves ensures that they react quickly to changes in flow direction. When fluid flows in the intended direction, the internal mechanism opens seamlessly. If there is any tendency for backflow, the valve disc or ball closes promptly, mitigating the risk of system failures or contamination.

Varieties of Cast Steel Check Valves

Cast steel check valves come in several configurations, each tailored to specific applications. The most common types include

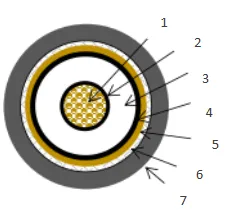

cast steel check valve

1. Swing Check Valves Featuring a swinging arm that pivots to open and close, this design is ideal for applications with lower flow velocities.

2. Lift Check Valves These valves utilize a disc that lifts off its seat to permit flow. They are suitable for high-velocity applications and are often more compact than swing check valves.

3. Dual Plate Check Valves Incorporating two discs that pivot on a hinge, this design minimizes pressure drop and is excellent for high-flow situations.

Each design offers unique advantages, and the selection often depends on the specific requirements of the system they are used in.

Applications

The applications of cast steel check valves are vast and varied. In the oil and gas industry, they are crucial in pipelines, ensuring that the transport of crude oil and natural gas remains efficient and safe. In water treatment facilities, these valves prevent backflow that could contaminate clean water supplies. Additionally, in the chemical processing sector, cast steel check valves help maintain the integrity of the system by controlling the flow of hazardous materials.

Conclusion

In conclusion, cast steel check valves are vital components in a multitude of industrial applications. Their robust construction, reliable operation, and versatility make them an ideal choice for high-pressure and high-temperature environments. As industries continue to evolve, the need for efficient and durable flow control solutions like cast steel check valves will remain paramount, ensuring the safety and efficacy of fluid transport systems across the globe.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024