10 月 . 07, 2024 00:40 Back to list

carbon steel ball check valve

Understanding Carbon Steel Ball Check Valves Functionality and Applications

In the world of fluid management systems, valves play a crucial role in regulating flow and ensuring the efficient operation of various processes. Among these, the ball check valve has carved out a significant niche, particularly for applications that require reliability and durability. This article explores the characteristics, functionality, and applications of carbon steel ball check valves.

What is a Ball Check Valve?

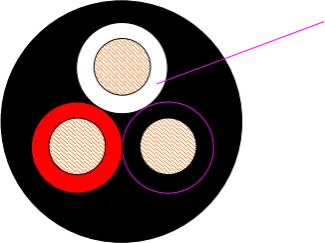

A ball check valve is a type of one-way valve that utilizes a spherical ball to prevent the backward flow of fluid. When fluid flows in the intended direction, the ball is pushed away from its seat, allowing free passage. Conversely, when there is a reverse flow, the ball is forced back into the seat, creating a seal that prevents fluid from moving upstream. This design not only ensures unidirectional flow but also protects equipment and systems from potential backflow damage.

Material Composition The Advantage of Carbon Steel

The choice of material for the ball check valve significantly influences its performance, durability, and cost-effectiveness. Carbon steel is a popular material for these valves due to its excellent mechanical properties, affordability, and adaptability to various environments.

1. Strength and Durability Carbon steel has a high tensile strength that can withstand the pressures encountered in industrial applications. This strength translates to longer service life and reduced maintenance requirements, making it a cost-effective choice in the long run.

2. Corrosion Resistance While carbon steel is susceptible to corrosion, manufacturers often apply protective coatings or treatments to enhance its resistance to rust and chemical degradation. This ensures that the valves maintain their integrity even when exposed to harsh environments.

3. Versatility Carbon steel ball check valves can be used in a wide range of industries, including water treatment, oil and gas, chemical processing, and HVAC systems. Their adaptability makes them a favored option among engineers and system designers.

How Do Carbon Steel Ball Check Valves Function?

The operation of a carbon steel ball check valve revolves around the simple yet effective mechanism of the ball. When fluid enters the valve from the inlet side, it applies pressure to the ball, which lifts and allows flow through the valve. When the flow direction changes or ceases, gravity and back pressure push the ball back onto its seat, closing the valve.

carbon steel ball check valve

This design not only allows for smooth operation with minimal resistance but also ensures that the valve requires no external power source or manual intervention. This automatic functioning is particularly beneficial in remote locations or applications where ongoing maintenance might be challenging.

Applications of Carbon Steel Ball Check Valves

Carbon steel ball check valves find utility across various applications due to their reliability and sturdy construction. Some common uses include

1. Pumping Systems In pumps, these valves prevent the backflow of fluids, ensuring efficient operation and protecting the pump from damage.

2. Water and Wastewater Treatment In municipal water systems, these valves are crucial for maintaining the integrity of the distribution system and preventing contamination.

3. Oil and Gas Industry They serve as critical components in pipelines, safeguarding against back pressure and ensuring consistent flow.

4. HVAC Systems Used in heating and cooling systems, they help maintain pressure and flow, preventing unwanted backflow that could affect system efficiency.

5. Chemical Processing In environments where corrosive substances are handled, carbon steel valves can be fitted with protective coatings to enhance durability while performing their function effectively.

Conclusion

In summary, carbon steel ball check valves are essential components in various fluid management systems, providing a reliable solution for preventing backflow and ensuring efficient operation. Their strength, durability, and versatility make them a preferred choice in numerous industries. As technology advances and industries evolve, the role of these valves will continue to be significant, ensuring the smooth operation of critical systems worldwide. Whether in manufacturing, water treatment, or energy production, carbon steel ball check valves are poised to remain indispensable.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024