2 月 . 15, 2025 07:56 Back to list

Flexible Rubber Cable

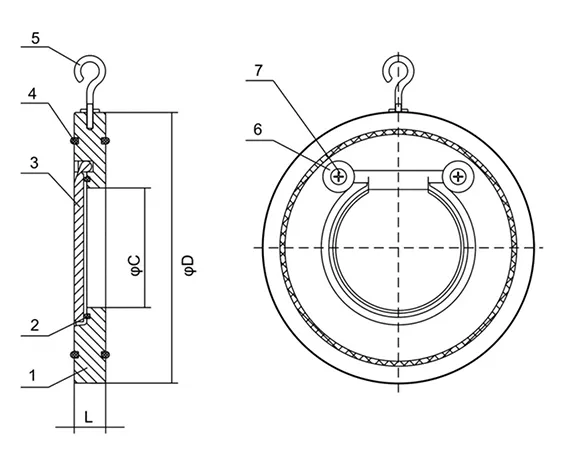

Carbon steel ball check valves serve as essential components within various industrial systems, owing to their robust design and reliability. These valves are engineered to permit fluid flow in one direction while preventing backflow, which could otherwise compromise system efficiency and safety. Known for their durability, carbon steel ball check valves excel in high-pressure environments where other materials might falter.

The trustworthiness of manufacturers specializing in carbon steel ball check valves further enhances the appeal of using these components in industrial applications. Companies that have established expertise in metallurgy and machining stand out, as they consistently produce valves that meet and often exceed industry standards. These manufacturers often offer certifications ensuring their products adhere to international quality norms, thus providing customers with the confidence that their operational needs will be met without compromise. Moreover, the real-world experience of engineers using carbon steel ball check valves further validates their expansive application. Testimonials frequently highlight the longevity and minimal maintenance requirements once these valves are integrated into a system. Additionally, the cost-effectiveness of carbon steel as a material contributes to overall reduced operational expenses, making it a strategic choice for businesses focused on optimizing budget allocation. In environmentally sensitive applications, carbon steel ball check valves align with modern sustainability goals. Their durability translates to reduced material waste over time since they require less frequent replacement. By choosing carbon steel, industries not only benefit from the immediate operational advantages but also contribute positively to environmental conservation efforts. In conclusion, the carbon steel ball check valve stands as a cornerstone of industrial efficiency and safety. With its robust construction, adept handling of varying pressures and temperatures, and reduced maintenance needs, it remains an expert-recommended choice across myriad sectors. Companies looking to enhance their systems' reliability and performance consistently turn to these valves, confident in the authority and trustworthiness established by longstanding industry leaders.

The trustworthiness of manufacturers specializing in carbon steel ball check valves further enhances the appeal of using these components in industrial applications. Companies that have established expertise in metallurgy and machining stand out, as they consistently produce valves that meet and often exceed industry standards. These manufacturers often offer certifications ensuring their products adhere to international quality norms, thus providing customers with the confidence that their operational needs will be met without compromise. Moreover, the real-world experience of engineers using carbon steel ball check valves further validates their expansive application. Testimonials frequently highlight the longevity and minimal maintenance requirements once these valves are integrated into a system. Additionally, the cost-effectiveness of carbon steel as a material contributes to overall reduced operational expenses, making it a strategic choice for businesses focused on optimizing budget allocation. In environmentally sensitive applications, carbon steel ball check valves align with modern sustainability goals. Their durability translates to reduced material waste over time since they require less frequent replacement. By choosing carbon steel, industries not only benefit from the immediate operational advantages but also contribute positively to environmental conservation efforts. In conclusion, the carbon steel ball check valve stands as a cornerstone of industrial efficiency and safety. With its robust construction, adept handling of varying pressures and temperatures, and reduced maintenance needs, it remains an expert-recommended choice across myriad sectors. Companies looking to enhance their systems' reliability and performance consistently turn to these valves, confident in the authority and trustworthiness established by longstanding industry leaders.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024