2 月 . 12, 2025 15:05 Back to list

MSS Metal Seat Gate Valve OS&Y

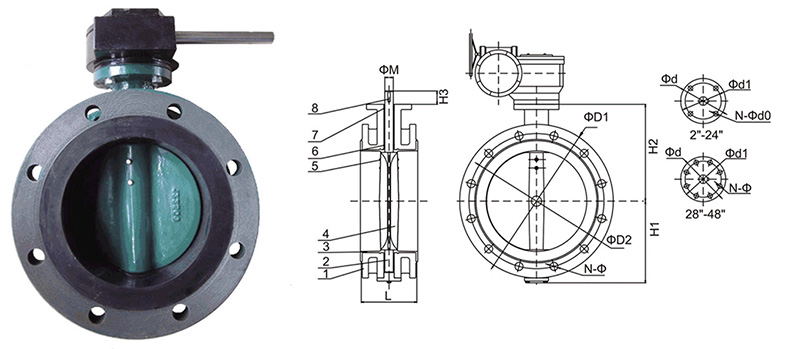

Choosing a reliable butterfly valve supplier can significantly impact the success of a wide range of industrial applications. This article delves into the most important factors to consider when selecting a butterfly valve supplier, aiming to enhance your understanding of what makes a supplier stand out in the crowded marketplace.

Authoritativeness is reflected in a supplier's market reputation and industry contributions. A reputable butterfly valve supplier is often recognized through certifications, awards, and memberships in professional organizations. Such credentials affirm their commitment to maintaining high-quality standards and staying updated with technological advances and regulatory changes. Check for ISO certifications or adherence to ANSI or API standards, as these indicate a rigorous approach to quality assurance and product reliability. Furthermore, authoritative suppliers often contribute to industry knowledge by publishing white papers, conducting workshops, or participating in industry conferences. Trustworthiness, the final pillar, forms the backbone of long-term business partnerships. A trustworthy supplier maintains transparency in all dealings, whether discussing product specifications, timelines, or pricing. They offer clear, honest communication and are upfront about any potential challenges or limitations. Trustworthy suppliers provide comprehensive warranties and reliable after-sales support, ensuring that any issues are promptly addressed. Customer testimonials and case studies are excellent resources for assessing a supplier's trustworthiness. Look for feedback that speaks to the supplier's reliability, integrity, and customer service quality. In addition to these core attributes, potential buyers should also consider the supplier's geographical proximity, production capacity, and logistical capabilities. Proximity can lead to faster delivery times and easier access to support services, which is invaluable in urgent situations. Suppliers with large production capacities and advanced logistics networks can better handle bulk orders, ensuring timely delivery even during peak demand. In conclusion, selecting the right butterfly valve supplier involves a balance of experience, expertise, authoritativeness, and trustworthiness. By thoroughly evaluating potential suppliers against these criteria, businesses can ensure they partner with an entity that not only meets their immediate needs but also supports their long-term operational efficiency. A strategic, careful selection process will lead to a successful partnership and guaranteed product satisfaction, ultimately enhancing the performance and reliability of any industrial flow control system.

Authoritativeness is reflected in a supplier's market reputation and industry contributions. A reputable butterfly valve supplier is often recognized through certifications, awards, and memberships in professional organizations. Such credentials affirm their commitment to maintaining high-quality standards and staying updated with technological advances and regulatory changes. Check for ISO certifications or adherence to ANSI or API standards, as these indicate a rigorous approach to quality assurance and product reliability. Furthermore, authoritative suppliers often contribute to industry knowledge by publishing white papers, conducting workshops, or participating in industry conferences. Trustworthiness, the final pillar, forms the backbone of long-term business partnerships. A trustworthy supplier maintains transparency in all dealings, whether discussing product specifications, timelines, or pricing. They offer clear, honest communication and are upfront about any potential challenges or limitations. Trustworthy suppliers provide comprehensive warranties and reliable after-sales support, ensuring that any issues are promptly addressed. Customer testimonials and case studies are excellent resources for assessing a supplier's trustworthiness. Look for feedback that speaks to the supplier's reliability, integrity, and customer service quality. In addition to these core attributes, potential buyers should also consider the supplier's geographical proximity, production capacity, and logistical capabilities. Proximity can lead to faster delivery times and easier access to support services, which is invaluable in urgent situations. Suppliers with large production capacities and advanced logistics networks can better handle bulk orders, ensuring timely delivery even during peak demand. In conclusion, selecting the right butterfly valve supplier involves a balance of experience, expertise, authoritativeness, and trustworthiness. By thoroughly evaluating potential suppliers against these criteria, businesses can ensure they partner with an entity that not only meets their immediate needs but also supports their long-term operational efficiency. A strategic, careful selection process will lead to a successful partnership and guaranteed product satisfaction, ultimately enhancing the performance and reliability of any industrial flow control system.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

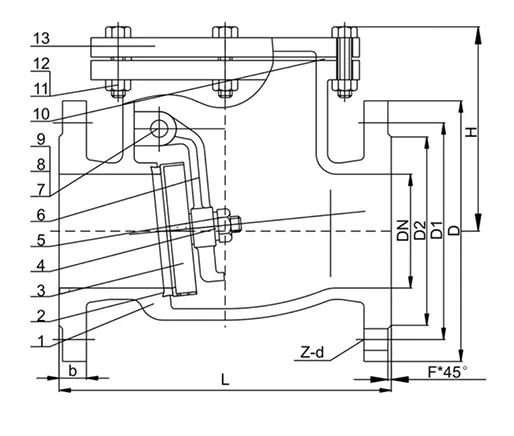

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024