12 月 . 03, 2024 18:29 Back to list

butterfly valve supplier

The Importance of Choosing the Right Butterfly Valve Supplier

When it comes to industries dealing with fluid control, the choice of valves can significantly impact the efficiency and effectiveness of operations. Among various types of valves, butterfly valves have gained popularity due to their compact design, lightweight construction, and low operating costs. However, selecting the right butterfly valve supplier is crucial to ensure the longevity, performance, and reliability of these components.

Understanding Butterfly Valves

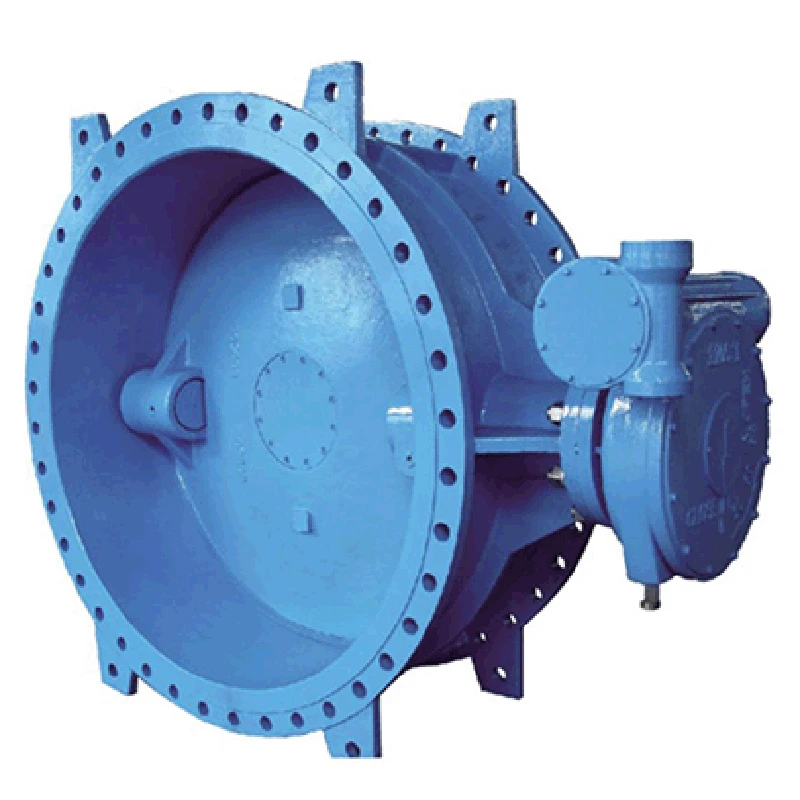

Butterfly valves are quarter-turn rotational valves that consist of a disk, which is a control element that regulates the flow of fluid through a pipe. When the disk is turned 90 degrees, it either allows or blocks the fluid flow. These valves are commonly used in various applications, including water distribution, wastewater treatment, pharmaceuticals, and food processing. Their unique design allows for quick and efficient operation, making them a preferred choice in many engineering projects.

Why Supplier Selection Matters

1. Quality Assurance The quality of the butterfly valves directly affects their performance and lifespan. A reputable supplier will provide products that meet industry standards and are made from high-quality materials. Choosing a supplier with a strong track record ensures that you receive reliable valves that can withstand the demands of your specific application.

2. Customization Options Different applications require different valve specifications. A good butterfly valve supplier will offer customization options, including size, material, and connection type. They can work closely with clients to provide tailored solutions that meet unique project requirements.

3. Technical Support and Expertise Navigating the technical aspects of butterfly valves can be complex. An experienced supplier will provide technical support and advice, helping you select the right valve for your needs. Their expertise can save you time and money by preventing costly mistakes related to improper valve selection.

butterfly valve supplier

4. After-Sales Service A supplier’s commitment doesn’t end after the sale. Reliable after-sales service is essential, as it includes assistance with installation, maintenance, and troubleshooting. A good supplier will provide resources and support to ensure the long-term success of your valve systems.

5. Competitive Pricing While cost should not be the sole factor in supplier selection, it remains an important consideration. A reputable butterfly valve supplier will offer competitive pricing without compromising on quality. It's essential to compare quotes and assess the overall value based on the quality of the products and services provided.

Finding the Right Supplier

To find the right butterfly valve supplier for your needs, start by conducting thorough research. Look for suppliers with strong reputations in the industry, verified customer reviews, and case studies showcasing successful projects. Attend trade shows and industry conferences to meet potential suppliers and gain insights into their offerings.

Moreover, consider suppliers that prioritize sustainability and environmental concerns. As industries increasingly adopt eco-friendly practices, collaborating with suppliers who share these values can enhance your company’s reputation and contribute to a greener future.

Conclusion

In conclusion, the selection of a butterfly valve supplier is a critical decision that can impact your operations significantly. By prioritizing quality, customization, technical support, after-sales service, and competitive pricing, you can ensure that your chosen supplier will meet your needs effectively. Investing time in finding the right supplier will not only enhance the performance of your butterfly valves but also contribute to the success of your projects in the long run. By making informed choices, you can optimize your fluid control systems and ensure reliable, efficient operations for years to come.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024