10 月 . 11, 2024 09:22 Back to list

butterfly valve flange end

Understanding Butterfly Valve Flange Ends An Overview

Butterfly valves are essential components in various industrial applications, primarily used for regulating and controlling the flow of fluids within pipelines. Among the various designs and configurations of butterfly valves, the flange end type plays a crucial role in ensuring effective sealing, easy installation, and maintenance. This article delves into the characteristics, benefits, and applications of butterfly valve flange ends.

What is a Butterfly Valve?

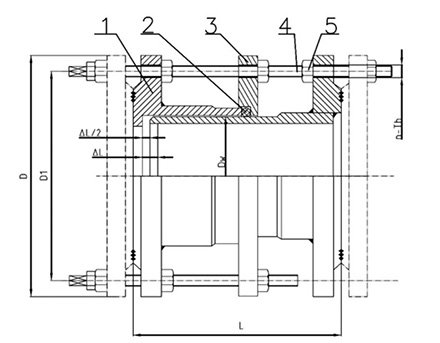

A butterfly valve consists of a circular disc or blade that rotates within a pipeline to control the flow of fluid. The disc is connected to a shaft, which allows it to pivot either vertically or horizontally to either permit or obstruct flow. Butterfly valves are renowned for their simplicity, compact design, and quick operating capabilities, making them popular in a wide range of industries.

Flange End Configuration

The flange end configuration refers to the method of connecting the butterfly valve to the pipeline. Flanges are flat or raised surfaces with holes that allow the valve to be bolted onto the pipe. This design provides a robust and leak-proof connection, ensuring reliability during operation. Flange ends come in various dimensions and types, including ANSI, DIN, and JIS standards, and they can accommodate diverse pipe sizes.

Advantages of Butterfly Valve Flange Ends

1. Ease of Installation Flange-end butterfly valves simplify the installation process as they can be easily bolted onto existing pipe flanges. This feature saves time and labor costs during setup, particularly in complex piping systems.

2. Reliable Sealing With proper gaskets and bolting, flange ends offer excellent sealing performance. This minimizes the risk of leaks, which can lead to costly repairs and environmental concerns.

3. Wide Range of Applications Due to their versatility, butterfly valves with flange ends are suitable for various applications, including water supply, wastewater treatment, heating, ventilation, and air conditioning systems (HVAC), and in chemical processing industries.

4. Cost-Effectiveness The simple design and ease of manufacturing of butterfly valves, particularly those with flange ends, result in lower costs compared to other valve types. Their efficiency and reliability also contribute to reduced operational costs over time.

butterfly valve flange end

5. Compact Design Unlike other valve types, flange-end butterfly valves are generally smaller and lighter, allowing for space-saving installations in tight environments.

Applications of Butterfly Valve Flange Ends

Butterfly valves with flange ends find extensive use in a variety of industries

- Water and Wastewater Treatment They regulate flow and manage pressure within treatment facilities, ensuring optimal processing of water resources.

- Chemical Processing In chemical plants, these valves control the flow of corrosive substances with precision, thanks to materials designed to withstand harsh conditions.

- Oil and Gas Industry Butterfly valves are crucial for controlling the flow of crude oil, gas, and other petroleum products, ensuring safe and efficient transport through pipelines.

- Food and Beverage Industry Cleanability and hygiene are paramount; thus, sanitary butterfly valves with flange ends are employed to meet stringent industry standards.

- HVAC Systems They help in maintaining air pressure and temperature control, enhancing overall energy efficiency in commercial and residential buildings.

Conclusion

Butterfly valve flange ends are integral to the functionality of fluid control systems across a multitude of applications. Their easy installation, reliable sealing, cost-effectiveness, and compact design make them an ideal choice for industries ranging from water treatment to chemical processing. As industries continue to evolve, the demand for efficient and durable fluid control solutions like butterfly valves will remain strong. Whether you’re in design, maintenance, or operation, understanding the significance of flange-end butterfly valves can prove valuable in ensuring a smooth and reliable flow management system.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024