2 月 . 12, 2025 16:16 Back to list

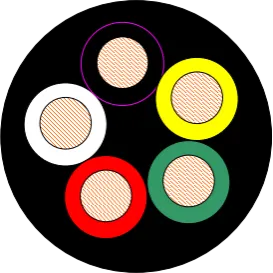

MC ( Type XHHW-2 )

Butterfly valve flange ends have revolutionized flow control in various industrial applications, providing efficiency, durability, and precision. As a seasoned professional in valve technology, I've witnessed the profound impact these components have on enhancing operational capabilities across industries.

Authoritative knowledge in the field also extends to understanding the standards and certifications that butterfly valve flange ends might adhere to. From ANSI and API standards in the United States to ISO regulations internationally, these certifications assure quality and compliance with industry norms, instilling confidence in purchasers about the product's reliability and performance. Maintaining trustworthiness in the competitive market for industrial valves requires stringent quality assurance processes. Each valve undergoes rigorous testing under simulated working conditions to verify its functionality and durability. This dedication to quality is crucial for preventing unexpected failures that could lead to operational downtimes or hazards. The adaptability of butterfly valve flange ends is yet another testament to their engineering excellence. They accommodate a wide range of actuator mechanisms, from manual handles to complex pneumatic or electric systems, allowing for easily customizable control solutions tailored to specific industrial needs. With decades of hands-on experience, I've seen that the correct implementation of butterfly valve flange ends can significantly optimize operational workflow. Consulting with experts during the selection and installation phases can help unveil hidden efficiencies and preemptively address potential challenges. In conclusion, butterfly valve flange ends offer unparalleled benefits in terms of performance, reliability, and efficiency. Their precise construction, compliance with stringent standards, and adaptability to different environments and systems underscore their indispensability in modern industry. Whether upgrading existing systems or installing new piping networks, the choice of a high-quality butterfly valve flange end can be a pivotal decision influencing the success and sustainability of industrial operations worldwide.

Authoritative knowledge in the field also extends to understanding the standards and certifications that butterfly valve flange ends might adhere to. From ANSI and API standards in the United States to ISO regulations internationally, these certifications assure quality and compliance with industry norms, instilling confidence in purchasers about the product's reliability and performance. Maintaining trustworthiness in the competitive market for industrial valves requires stringent quality assurance processes. Each valve undergoes rigorous testing under simulated working conditions to verify its functionality and durability. This dedication to quality is crucial for preventing unexpected failures that could lead to operational downtimes or hazards. The adaptability of butterfly valve flange ends is yet another testament to their engineering excellence. They accommodate a wide range of actuator mechanisms, from manual handles to complex pneumatic or electric systems, allowing for easily customizable control solutions tailored to specific industrial needs. With decades of hands-on experience, I've seen that the correct implementation of butterfly valve flange ends can significantly optimize operational workflow. Consulting with experts during the selection and installation phases can help unveil hidden efficiencies and preemptively address potential challenges. In conclusion, butterfly valve flange ends offer unparalleled benefits in terms of performance, reliability, and efficiency. Their precise construction, compliance with stringent standards, and adaptability to different environments and systems underscore their indispensability in modern industry. Whether upgrading existing systems or installing new piping networks, the choice of a high-quality butterfly valve flange end can be a pivotal decision influencing the success and sustainability of industrial operations worldwide.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024