10 月 . 30, 2024 21:08 Back to list

butterfly valve flange end

Understanding Butterfly Valve Flange Ends A Comprehensive Overview

Butterfly valves are widely used in various industrial applications for regulating and isolating fluid flow. Their design allows for quick operation and minimal pressure drop, making them an ideal choice in many settings. Among the various configurations of butterfly valves, the flange end connection is one of the most common. This article delves into the characteristics, advantages, and considerations of butterfly valves with flange ends.

What is a Butterfly Valve with Flange Ends?

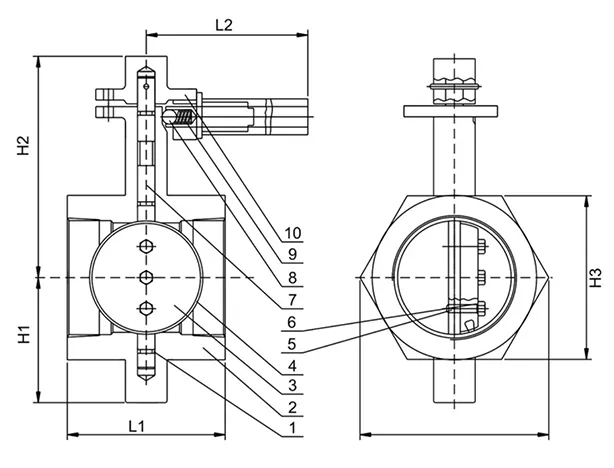

A butterfly valve features a rotating disc that acts as a throttle to control flow. The flange end connection refers to the way the valve is attached to piping systems, using flanges that allow for a secure and leak-proof connection. Flanges are flat plates with holes for bolts, which enable the valve to be bolted directly to the pipes at either end. This connection method is prevalent in both metallic and non-metallic piping systems.

Key Characteristics

1. Design Butterfly valves with flange ends typically come in two types lugged and wafer-style. Lugged butterfly valves have threaded holes for bolts attached to the valve body, while wafer-style valves fit between two flanges without bolts through the body itself.

2. Materials These valves are often constructed from various materials, including cast iron, stainless steel, and PVC. The choice of material depends on the application, whether it is handling corrosive substances, high pressures, or extreme temperatures.

3. Sizes and Ratings Flanged butterfly valves come in a wide range of sizes, accommodating different pipeline diameters. They also adhere to pressure ratings such as ANSI, DIN, or JIS, indicating their suitability for various pressure levels.

Advantages of Flange End Butterfly Valves

butterfly valve flange end

1. Ease of Installation The flange design allows for straightforward installation and maintenance. The ability to bolt the valve to the piping means it can be easily replaced or serviced without extensive modifications.

2. Versatility These valves can be used in diverse applications, including water treatment, HVAC systems, chemical processing, and more, making them highly versatile in industrial settings.

3. Efficiency With a minimal pressure drop across the valve when fully opened, butterfly valves enhance flow efficiency, contributing to better system performance.

4. Cost-Effectiveness Generally, butterfly valves are more economical than other valve types, particularly for larger diameters. The use of flange connections further simplifies logistics and installation costs.

Considerations

When selecting a butterfly valve with flange ends, it’s essential to consider factors such as the type of medium being transported, pressure and temperature conditions, and the specific design requirements of the system. Ensuring that the right material is chosen, along with appropriate sealing options, can significantly influence the valve's performance and longevity.

Conclusion

Butterfly valves with flange ends are a vital component in many industrial systems. Their design, combined with the advantages of flange connections, makes them a popular choice for flow control applications. By understanding the characteristics and benefits of these valves, engineers and system designers can make informed decisions that optimize both performance and reliability in their operations. Whether in water treatment, chemical processing, or other fields, flange end butterfly valves continue to play a critical role.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024