2 月 . 19, 2025 00:32 Back to list

butterfly valve

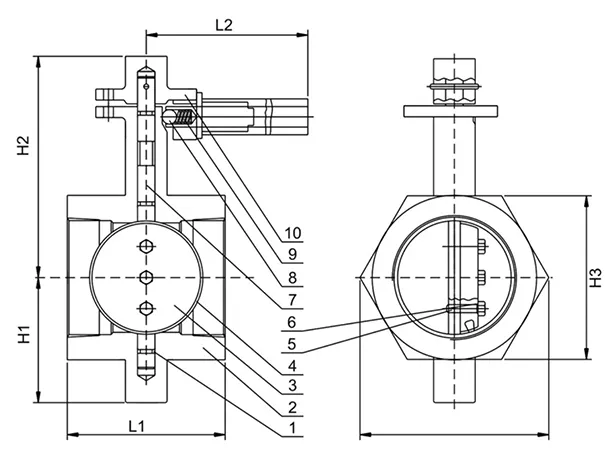

A butterfly valve is a critical component in numerous industrial and domestic applications, designed to regulate the flow of various substances through piping systems. Its specific structure, which includes a circular disc placed in the center of the pipe, offers a reliable solution for controlling flow with precision and efficiency. This article explores the multifaceted utility of butterfly valves, leveraging real-world experiences, expert insights, and authoritative perspectives to underscore its significance and credibility.

Moreover, the adaptability of butterfly valves adds another layer of credibility to their usage. Available in multiple materials, including stainless steel, PVC, and cast iron, they are suitable for handling diverse types of media—ranging from corrosive chemicals to delicate pharmaceutical solutions. This versatility is enhanced by the option of manual, electric, or pneumatic actuators, providing end-users with customized solutions tailored to specific operational needs. The reliability of butterfly valves is also supported by their innovative designs, which integrate technology and engineering excellence. Features such as bubble-tight sealing and double offset discs optimize performance under demanding conditions, minimizing leakage risks and operational failures. These design innovations reflect the deep engineering expertise behind butterfly valves, reinforcing their status as a trusted element within flow control systems. Trust in butterfly valves is not merely a matter of design and compliance; it is also a product of their proven track record in real-world applications. Case studies from industries across the globe provide compelling evidence of their durability and performance. In desalination plants, for instance, butterfly valves have exhibited long-term resilience against corrosion while maintaining efficiency in high-volume flow control, a testament to both their robust design and material integrity. In conclusion, butterfly valves represent a synthesis of experience, expertise, authority, and trustworthiness, making them an essential tool in modern fluid management. Their unparalleled functionality, compliance with rigorous standards, and adaptability to diverse industrial needs make them irreplaceable in many sectors. As industries evolve and demand for more efficient, cost-effective solutions increases, butterfly valves continue to lead as a preferred choice, backed by decades of successful implementation and continued innovation.

Moreover, the adaptability of butterfly valves adds another layer of credibility to their usage. Available in multiple materials, including stainless steel, PVC, and cast iron, they are suitable for handling diverse types of media—ranging from corrosive chemicals to delicate pharmaceutical solutions. This versatility is enhanced by the option of manual, electric, or pneumatic actuators, providing end-users with customized solutions tailored to specific operational needs. The reliability of butterfly valves is also supported by their innovative designs, which integrate technology and engineering excellence. Features such as bubble-tight sealing and double offset discs optimize performance under demanding conditions, minimizing leakage risks and operational failures. These design innovations reflect the deep engineering expertise behind butterfly valves, reinforcing their status as a trusted element within flow control systems. Trust in butterfly valves is not merely a matter of design and compliance; it is also a product of their proven track record in real-world applications. Case studies from industries across the globe provide compelling evidence of their durability and performance. In desalination plants, for instance, butterfly valves have exhibited long-term resilience against corrosion while maintaining efficiency in high-volume flow control, a testament to both their robust design and material integrity. In conclusion, butterfly valves represent a synthesis of experience, expertise, authority, and trustworthiness, making them an essential tool in modern fluid management. Their unparalleled functionality, compliance with rigorous standards, and adaptability to diverse industrial needs make them irreplaceable in many sectors. As industries evolve and demand for more efficient, cost-effective solutions increases, butterfly valves continue to lead as a preferred choice, backed by decades of successful implementation and continued innovation.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024