1 月 . 06, 2025 10:37 Back to list

butterfly valve

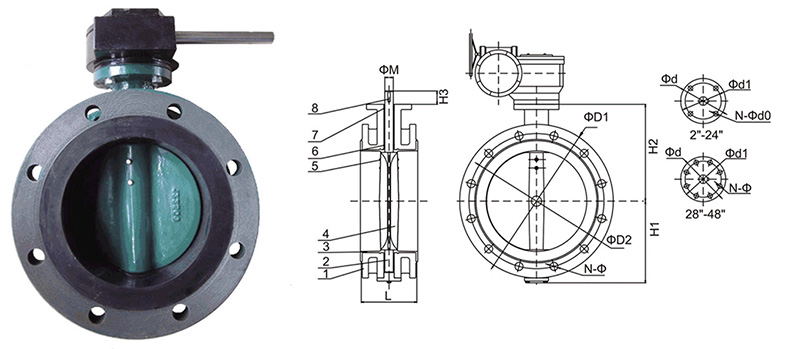

As an industry insider gazing upon the expansive world of industrial components, the butterfly valve stands out not only for its uniqueness but for its indispensable role across diverse applications. Its elegance lies in its simplicity, offering robust functionality that appeals to both seasoned engineers and newcomers alike. Whether you’re tasked with managing fluids in a large-scale plant or simply curious about the mechanisms behind everyday utilities, the butterfly valve is worth exploring.

At its core, the butterfly valve is a member of the quarter-turn valve family, distinctively named for its wing-like disc, which rotates around an axis perpendicular to the flow of the medium. This design makes it particularly effective in applications that require regulation or isolation with only a slight loss of pressure. The butterfly valve’s versatility flourishes across various industries, including oil and gas, water treatment, and chemical processing.

Understanding the practical expertise that accompanies the butterfly valve is essential. The valve's compact size and lighter weight, compared to other valve types, make it an ideal choice for installations where space and weight are a concern. Its straightforward mechanism — a disc situated in the middle of a pipe — allows for easy operation, especially in mediums that demand quick shutoffs. Engineers often favor butterfly valves because they can accommodate a wide range of sizes and materials, catering to diverse application needs and allowing for optimal material compatibility with different flow types and temperatures.

From an expert’s lens, the strengths of the butterfly valve shine bright in scenarios demanding efficient throttling of fluid streams. Its capability to handle large flow volumes with minimal pressure drop is unmatched. Moreover, the valve's design is conducive to maintaining a tight seal against various pressures within systems, made possible by advancements in seat designs and sealing technologies. Such innovations continue to bolster the butterfly valve’s reputation for durability and reliability, even in the harshest environments.

butterfly valve

The authoritativeness of butterfly valves comes not only from their proven track record in demanding industrial settings but from continuous innovations. Recent developments have seen the introduction of high-performance butterfly valves that offer enhanced functionality — able to withstand extreme temperatures and corrosive materials, thereby broadening their application horizons. Manufacturers invest heavily in research and development to improve valve performance, ensuring they meet stringent industry standards such as ANSI, API, and ISO certifications.

Trustworthiness in butterfly valve selection and usage is underscored by industry standards and rigorous testing. Partnering with recognized manufacturers can provide assurance of quality and performance. When sourcing a butterfly valve, considering factors such as valve type (centric, double-offset, or triple-offset), material composition, and specific application requirements ensures a strategic fit for the intended use. Engaging with suppliers who offer comprehensive technical support and after-sales service further enhances decision-making confidence.

In conclusion, the butterfly valve exemplifies a commendable balance of efficiency, adaptability, and innovation. Its presence in virtually every segment of manufacturing and utility services underscores its unparalleled significance. Understanding its applications, bolstered by expertise and authoritativeness, offers invaluable insights into enhancing system efficiencies. As industries evolve, heavily relying on the synergy between innovation and reliability, the butterfly valve continues to secure its place as a pivotal component in fluid control systems worldwide.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024