2 月 . 12, 2025 17:20 Back to list

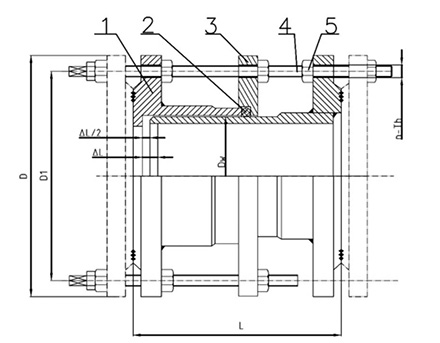

butterfly check valve

The butterfly check valve, though seemingly just another mechanical invention, holds a pivotal role in fluid dynamics and engineering applications. With decades of industry expertise and product development behind it, this fitting marvel of engineering addresses critical needs for both small-scale and industrial fluid control systems. Delving into its functionality and benefits can offer valuable insights into why it is a top choice for engineers and industries worldwide.

Engineers and industry experts often herald butterfly check valves for their efficiency in achieving a tight shut-off. The potential for leaks is substantially reduced due to the disc's ability to seal firmly against the valve seat. This feature makes them a trustworthy choice for applications where the integrity of fluid containment is critical, such as in water treatment facilities, food processing plants, and critical infrastructure systems. Authoritativeness in the realm of fluid mechanics and valve technology is essential, and butterfly check valves have been studied extensively to validate their efficacy and performance. Studies and real-world applications have consistently shown that these valves maintain performance standards over time while requiring minimal maintenance. This not only instills confidence among industry professionals but also makes them a cost-effective solution over the product lifecycle. Trustworthiness forms the bedrock of the butterfly check valve’s appeal. Professionals across various industries have come to rely on these valves for consistent performance, ease of installation, and longevity. Manufacturers often back their products with extensive warranties and customer support services, reflecting their confidence in the product. In conclusion, the butterfly check valve emerges as a paragon of engineering excellence, trusted expertise, and authoritative design. Its significance in the fluid dynamics industry cannot be overstated, as it not only meets but often exceeds the expectations of both engineers and end-users. Whether for new installations or system upgrades, the choice of integrating butterfly check valves into fluid control systems is one that guarantees efficiency, reliability, and peace of mind. For industries striving to maintain seamless operations and optimal environmental compliance, this valve is an indispensable asset.

Engineers and industry experts often herald butterfly check valves for their efficiency in achieving a tight shut-off. The potential for leaks is substantially reduced due to the disc's ability to seal firmly against the valve seat. This feature makes them a trustworthy choice for applications where the integrity of fluid containment is critical, such as in water treatment facilities, food processing plants, and critical infrastructure systems. Authoritativeness in the realm of fluid mechanics and valve technology is essential, and butterfly check valves have been studied extensively to validate their efficacy and performance. Studies and real-world applications have consistently shown that these valves maintain performance standards over time while requiring minimal maintenance. This not only instills confidence among industry professionals but also makes them a cost-effective solution over the product lifecycle. Trustworthiness forms the bedrock of the butterfly check valve’s appeal. Professionals across various industries have come to rely on these valves for consistent performance, ease of installation, and longevity. Manufacturers often back their products with extensive warranties and customer support services, reflecting their confidence in the product. In conclusion, the butterfly check valve emerges as a paragon of engineering excellence, trusted expertise, and authoritative design. Its significance in the fluid dynamics industry cannot be overstated, as it not only meets but often exceeds the expectations of both engineers and end-users. Whether for new installations or system upgrades, the choice of integrating butterfly check valves into fluid control systems is one that guarantees efficiency, reliability, and peace of mind. For industries striving to maintain seamless operations and optimal environmental compliance, this valve is an indispensable asset.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024