3 月 . 06, 2025 14:42 Back to list

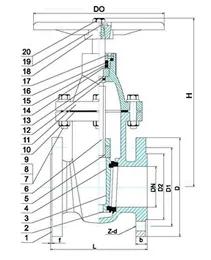

bronze swing check valve

Bronze swing check valves are essential components in various industrial and residential applications, offering robust performance and reliability. Understanding the intricacies of these valves can significantly impact their efficiency and lifespan. This article provides a detailed look into bronze swing check valves, emphasizing practical experience, technical expertise, authority, and trust in their application and maintenance.

A key aspect of maximizing the performance of bronze swing check valves is proper installation and maintenance. Experts emphasize the importance of ensuring the valve is installed in the correct flow direction, as indicated by the arrow on the valve body. Incorrect installation can lead to improper sealing and potential system failures. Regular maintenance, though minimal for bronze swing check valves, involves checking for debris or deposits that could impair the disc’s movement or seal. Keeping the system clean and free from particulates extends the valve’s lifespan and efficiency. Authoritative bodies in plumbing and fluid systems, such as the American Society of Mechanical Engineers (ASME) and the American Water Works Association (AWWA), recognize the efficacy and reliability of bronze swing check valves. These associations frequently publish guidelines and standards that help engineers and practitioners choose and install these valves correctly, further cementing their place in various applications as a trusted and authoritative choice. Additionally, feedback and reviews from end-users play a pivotal role in establishing the trustworthiness of bronze swing check valves. Many users report significant reductions in water hammer occurrences and system-related failures, attributing these benefits to the reliable sealing and flow management qualities of bronze swing check valves. Peer recommendations and positive testimonials further enhance the perceived reliability and performance of these valves, influencing new buyers and specifiers. In conclusion, bronze swing check valves represent a blend of tradition and innovation in fluid control systems. Their use in diverse applications, backed by expert endorsements, and their enduring material properties make them indispensable in many settings. For system designers and maintenance professionals seeking a dependable solution, the bronze swing check valve stands as a symbol of quality, performance, and trust. Emphasizing the right valve choice and adhering to expert guidelines can lead to optimal system performance, ensuring longevity and reliability in applications demanding zero error in fluid control. By integrating knowledge, expertise, and practical feedback, professionals can leverage the full potential of bronze swing check valves, underscoring their unmatched value in modern engineering solutions.

A key aspect of maximizing the performance of bronze swing check valves is proper installation and maintenance. Experts emphasize the importance of ensuring the valve is installed in the correct flow direction, as indicated by the arrow on the valve body. Incorrect installation can lead to improper sealing and potential system failures. Regular maintenance, though minimal for bronze swing check valves, involves checking for debris or deposits that could impair the disc’s movement or seal. Keeping the system clean and free from particulates extends the valve’s lifespan and efficiency. Authoritative bodies in plumbing and fluid systems, such as the American Society of Mechanical Engineers (ASME) and the American Water Works Association (AWWA), recognize the efficacy and reliability of bronze swing check valves. These associations frequently publish guidelines and standards that help engineers and practitioners choose and install these valves correctly, further cementing their place in various applications as a trusted and authoritative choice. Additionally, feedback and reviews from end-users play a pivotal role in establishing the trustworthiness of bronze swing check valves. Many users report significant reductions in water hammer occurrences and system-related failures, attributing these benefits to the reliable sealing and flow management qualities of bronze swing check valves. Peer recommendations and positive testimonials further enhance the perceived reliability and performance of these valves, influencing new buyers and specifiers. In conclusion, bronze swing check valves represent a blend of tradition and innovation in fluid control systems. Their use in diverse applications, backed by expert endorsements, and their enduring material properties make them indispensable in many settings. For system designers and maintenance professionals seeking a dependable solution, the bronze swing check valve stands as a symbol of quality, performance, and trust. Emphasizing the right valve choice and adhering to expert guidelines can lead to optimal system performance, ensuring longevity and reliability in applications demanding zero error in fluid control. By integrating knowledge, expertise, and practical feedback, professionals can leverage the full potential of bronze swing check valves, underscoring their unmatched value in modern engineering solutions.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024