11 月 . 02, 2024 13:38 Back to list

bidirectional knife gate valve

Understanding Bidirectional Knife Gate Valves

Bidirectional knife gate valves are critical components in various industrial applications, designed to facilitate the control of fluid flow. These valves are particularly renowned for their ability to isolate flow in both directions while preventing leakage, which is crucial for maintaining system integrity and safety.

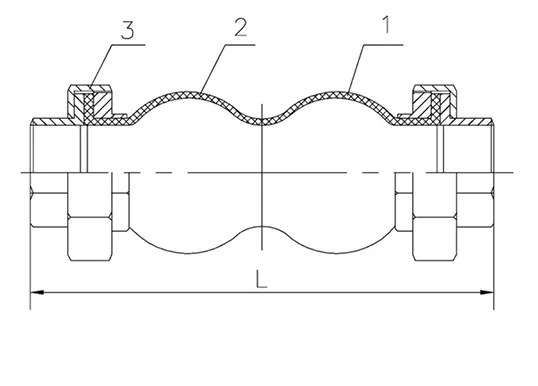

The design of a bidirectional knife gate valve features a blade-like gate that slides between two seats, effectively cutting through the media, be it liquid or solid. This unique mechanism allows for reliable shut-off, making it an ideal choice in sectors such as wastewater treatment, mining, pulp and paper production, and chemical processing. The knife gate design makes it possible to handle challenging materials that may include slurries, sludges, and other viscous substances without clogging or jamming.

One of the key advantages of bidirectional knife gate valves is their ability to provide flow control in both upstream and downstream directions. This flexibility is vital in systems that require the regulation of flow under varying operational conditions. By allowing flow in either direction, these valves enhance system efficiency and enable more sophisticated process control strategies.

bidirectional knife gate valve

Another notable feature of bidirectional knife gate valves is their robust construction. Typically made from materials such as stainless steel, cast iron, or other corrosion-resistant alloys, these valves can endure harsh operating conditions, including fluctuating pressures and temperatures. Additionally, the design minimizes turbulence and energy loss, which contributes to overall system performance.

Maintenance is another critical consideration for any industrial valve. Bidirectional knife gate valves are often designed for easy maintenance, with accessible components that can be serviced without the need for complete valve removal. This ease of maintenance not only reduces downtime but also lowers operational costs, making them a cost-effective solution over the valve’s lifetime.

When selecting a bidirectional knife gate valve, it is important to consider various factors such as the type of media being handled, the required pressure ratings, and the specific application environment. Moreover, proper sizing is vital to ensure optimal performance; an incorrect size can lead to inefficiencies and potential system failures.

In conclusion, bidirectional knife gate valves are a versatile and reliable choice for fluid control in a variety of industries. Their unique design allows for effective media isolation in both flow directions, making them indispensable in applications that demand precision and reliability. With their durability, low maintenance needs, and ability to handle challenging materials, these valves continue to play a pivotal role in advancing industrial processing techniques and ensuring the safe and efficient operation of fluid management systems. As industries evolve and seek greater efficiencies, the importance of high-quality valves like the bidirectional knife gate valve is more critical than ever.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024