9 月 . 02, 2024 09:01 Back to list

Bidirectional Knife Gate Valve - Reliable Flow Control Solutions

Understanding the Bidirectional Knife Gate Valve

The bidirectional knife gate valve is an essential component widely used in various industries, including water treatment, mining, and pulp and paper. This valve is designed to control the flow of fluids and slurries in challenging applications. Its unique features and construction make it particularly suitable for environments where heavy solids or critical flow control is needed.

Structure and Design

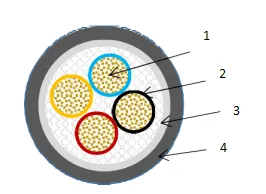

The bidirectional knife gate valve comprises a robust body, a gate (or blade), and an actuator mechanism. The body is typically made from materials such as carbon steel, stainless steel, or other alloys, depending on the application requirements. The gate is a flat, sharp-edged blade that can effectively cut through the media, allowing for a tight seal when closed and minimal resistance when open.

One of the key advantages of a bidirectional knife gate valve is its ability to function in both directions. Unlike traditional gate valves that may only operate in one flow direction, the bidirectional design allows for flexible installation and operation. This feature is particularly beneficial in applications where the flow direction may change or needs to be reversed for maintenance.

Working Principle

The operating mechanism of the knife gate valve is straightforward. The gate is raised or lowered by an actuator, which can be manually operated or automated using pneumatic, electric, or hydraulic systems. When the gate is lowered, it slides down into the seat, effectively blocking the flow of the medium. Conversely, when the gate is raised, it retracts from the flow path, allowing the medium to pass freely.

The knife edge design of the gate allows it to cut through solids present in the slurry, preventing clogs that might occur with conventional valve types. This design is especially advantageous in industries dealing with viscous fluids or mixtures containing solid particles.

bidirectional knife gate valve

Applications

Bidirectional knife gate valves find their applications in a variety of sectors. In wastewater treatment plants, they are used to manage the flow of sludge and sewage, ensuring that the systems operate smoothly without blockages. In mining operations, these valves help regulate the flow of abrasive slurries, contributing to efficient resource extraction and processing.

Additionally, the pulp and paper industry utilizes these valves for controlling the flow of pulp and other viscous materials. The ability to handle a wide range of temperatures and pressures makes them versatile for different processing conditions in these industries.

Advantages

The bidirectional knife gate valve offers several advantages. Its ability to handle viscous and solid-laden fluids without clogging enhances operational efficiency. Furthermore, the robust construction ensures longevity and reliability, reducing maintenance costs. The versatility in installation and operation enhances productivity, allowing for swift changes in flow direction when necessary.

Conclusion

In conclusion, the bidirectional knife gate valve is a vital piece of equipment in various industrial applications. Its robust design, ability to handle challenging media, and adaptability to different operational demands make it an invaluable tool for managing flow control. As industries continue to evolve and demand more efficient solutions, the bidirectional knife gate valve will remain a critical component in fluid handling systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024