10 月 . 06, 2024 03:04 Back to list

basket strainer

Understanding Basket Strainers Essential Components for Fluid Management

In various industrial and commercial applications, managing the flow of liquids is paramount. One essential component in ensuring fluid efficacy and safety is the basket strainer. This device plays a critical role in maintaining the purity and quality of liquids by filtering out unwanted debris and particles. This article delves into the functionality, types, and applications of basket strainers, highlighting their importance in fluid management systems.

What is a Basket Strainer?

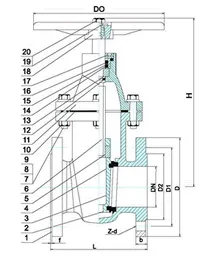

A basket strainer is a type of filter designed to remove solid particles from liquids in a piping system. Typically made from stainless steel or other durable materials, it consists of a basket-shaped filter element that catches debris while allowing clean fluid to pass through. The design enables easy cleaning and maintenance, making basket strainers suitable for various applications.

How Does It Work?

The mechanism of a basket strainer is relatively simple yet effective. As fluid flows through the pipeline and enters the strainer, it encounters the filter basket, which is perforated with holes or mesh that fit the desired particle size to be filtered out. The suspended solids are trapped in the basket, while the clean fluid continues its journey through the system.

To maintain optimal performance, periodic monitoring and cleaning of the basket strainer are necessary. Depending on the type of application and the amount of debris present in the fluid, the cleaning frequency may vary. Most basket strainers come with a bolted cover or clean-out port, providing easy access for maintenance.

Types of Basket Strainers

There are several types of basket strainers, each designed for specific applications

basket strainer

1. Y-Strainers These are designed in a “Y” shape and are often used in small piping systems. Their compact size makes them ideal for tight spaces while still effectively filtering out debris.

2. T-Strainers Shaped like a “T,” these strainers are used in larger pipelines and can handle higher volumes of fluid. They typically offer a larger surface area for collecting debris.

3. Inline Basket Strainers These are installed directly into the piping system and facilitate easy access for maintenance, making them a popular choice for systems that require frequent cleaning.

4. Temporary Strainers Used for short-term applications or during maintenance periods, these strainers are designed to provide quick filtration without long-term installation.

Applications of Basket Strainers

Basket strainers are utilized across numerous sectors, including water treatment, oil and gas, food and beverage production, HVAC systems, and many more. They are particularly essential in industries where the integrity of the fluid is critical. For instance, in the food and beverage sector, ensuring that contaminants do not compromise product quality is vital. Similarly, in oil and gas settings, the prevention of particulate matter from damaging equipment is paramount.

Conclusion

In conclusion, basket strainers are indispensable components in managing fluid systems across various industries. Their design, which allows for the efficient filtration of particles, combined with their ease of maintenance, makes them a preferred option in many applications. By ensuring that only clean fluid flows through the system, basket strainers protect valuable equipment, enhance product quality, and facilitate the smooth operation of processes. As industries evolve and demand for efficiency increases, the role of basket strainers in fluid management will undoubtedly remain significant.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024