2 月 . 03, 2025 01:53 Back to list

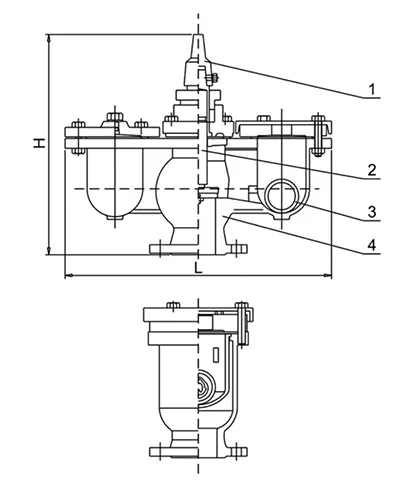

basket strainer

A basket strainer might seem like a simple component in an extensive piping system, but its importance cannot be overstated. For industries where fluid purity is paramount, such as chemical processing, food and beverage, and oil and gas, basket strainers serve as an essential safeguard, preventing debris from entering and damaging pumps, valves, and other critical components. With robust construction and adaptable designs, these strainers enhance operational efficiency and protect significant investments in equipment and infrastructure.

Trustworthiness in manufacturing and supply is non-negotiable. A reliable provider ensures that every basket strainer undergoes rigorous quality checks and is compliant with industry standards such as ASME, API, and DIN. Transparency in material sourcing and documented quality assurance not only certifies product reliability but builds a foundation of trust with clients. Client testimonials and case studies also play a critical role—real-world evidence of performance bolsters confidence in the product’s claimed benefits. Basket strainers are a small component that makes a huge difference. Their ability to filter and protect ensures process reliability and system integrity. Companies that understand the nuances of their operations and choose their strainers with care ensure long-term success and efficiency gains. Investing in quality basket strainers is investing in the dependability and excellence of the entire operation. While the initial cost might be higher for premium strainers, the long-term benefits, including lower maintenance, reduced equipment failure, and improved process continuity, present a cost-saving narrative that resonates across industries. In conclusion, while the initial outlay for a high-quality basket strainer might be more substantial, the decision pays for itself through longevity, peace of mind, and seamless operational flow. By navigating the options with a nuanced understanding and recognizing the role of expert guidance, it is possible to make decisions that align with both current needs and future demands. Consistent performance and resilience are the hallmarks of a well-chosen basket strainer, underscoring its silent yet significant contribution to industrial success.

Trustworthiness in manufacturing and supply is non-negotiable. A reliable provider ensures that every basket strainer undergoes rigorous quality checks and is compliant with industry standards such as ASME, API, and DIN. Transparency in material sourcing and documented quality assurance not only certifies product reliability but builds a foundation of trust with clients. Client testimonials and case studies also play a critical role—real-world evidence of performance bolsters confidence in the product’s claimed benefits. Basket strainers are a small component that makes a huge difference. Their ability to filter and protect ensures process reliability and system integrity. Companies that understand the nuances of their operations and choose their strainers with care ensure long-term success and efficiency gains. Investing in quality basket strainers is investing in the dependability and excellence of the entire operation. While the initial cost might be higher for premium strainers, the long-term benefits, including lower maintenance, reduced equipment failure, and improved process continuity, present a cost-saving narrative that resonates across industries. In conclusion, while the initial outlay for a high-quality basket strainer might be more substantial, the decision pays for itself through longevity, peace of mind, and seamless operational flow. By navigating the options with a nuanced understanding and recognizing the role of expert guidance, it is possible to make decisions that align with both current needs and future demands. Consistent performance and resilience are the hallmarks of a well-chosen basket strainer, underscoring its silent yet significant contribution to industrial success.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024