9 月 . 26, 2024 09:40 Back to list

ball valve with y strainer

Ball Valve with Y Strainer An Essential Component in Fluid Systems

In various industrial applications and plumbing systems, the efficient management and control of fluid flow are crucial. Among the myriad of components that contribute to this efficiency, the combination of a ball valve with a Y strainer stands out as an essential solution for maintaining optimal flow characteristics and protecting downstream systems from contaminants.

Understanding the Components

A ball valve is a type of valve that uses a hollow, perforated, and pivoting ball to control the flow of fluid. When the ball's hole is aligned with the flow direction, the valve is open, allowing fluid to pass through. Conversely, when the ball is rotated 90 degrees, the flow is blocked. This mechanism allows for quick and straightforward on/off control of fluid movement, making ball valves an ideal choice for applications where prompt response is required.

A Y strainer, on the other hand, is a filtration device that removes unwanted particles and debris from the fluid flow. The design of a Y strainer resembles the letter Y, and it typically incorporates a mesh or perforated screen within its body. This screen traps solid contaminants while allowing the fluid to flow through unimpeded. The combination of effective filtration with minimal pressure loss is a hallmark of Y strainers, making them invaluable in protecting sensitive equipment and ensuring the longevity of system components.

The Advantages of Using a Ball Valve with Y Strainer

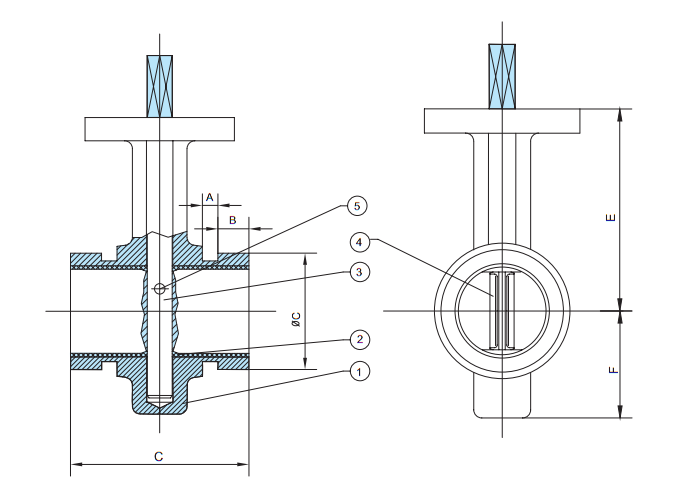

ball valve with y strainer

1. Enhanced Protection Integrating a Y strainer with a ball valve provides an added layer of protection for pumps, compressors, and other sensitive equipment. By filtering out debris and particulate matter, the strainer helps prevent blockages and damage, which can lead to costly repairs and downtime.

2. Improved Efficiency The streamlined design of a ball valve, combined with the efficient filtration of a Y strainer, minimizes pressure drops within the fluid system. This efficient flow control not only saves energy but also enhances the overall performance of the entire system.

3. Ease of Maintenance Maintenance is often cited as a critical concern in fluid handling systems. The combination of a ball valve and a Y strainer facilitates easier cleaning and replacement of components. The Y strainer can easily be removed and cleaned, ensuring that the filtration system remains efficient over time.

4. Versatility This combination is suitable for a wide range of applications, from water treatment facilities to chemical processing plants. The robustness and reliability of both components make them adaptable to various fluid applications, including aggressive and viscous fluids.

Conclusion

The integration of a ball valve with a Y strainer represents a smart engineering solution for fluid handling systems. By offering precise flow control and effective filtration, this combination ensures operational efficiency and equipment longevity. As industries continue to evolve and seek ways to optimize their processes, understanding and implementing these essential components will remain critical in achieving desired outcomes. Whether in industrial applications, plumbing, or HVAC systems, the ball valve and Y strainer duo will undoubtedly play a vital role in the management and protection of fluid systems worldwide.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024