11 月 . 01, 2024 13:25 Back to list

Exploring the Benefits and Applications of Ball Valves in Various Industries

Understanding Ball Valves A Key Component in Fluid Control

Ball valves are one of the most essential types of valves used in various industrial applications today. Their design, functionality, and efficiency make them a preferred choice for controlling fluid flow in pipes and other systems. This article will explore the features, advantages, and applications of ball valves.

What is a Ball Valve?

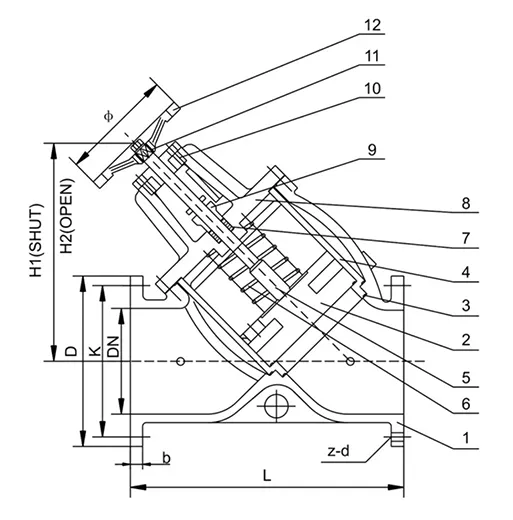

A ball valve is a type of quarter-turn valve that uses a spherical disc, known as a ball, to control the flow of fluid. The ball has a hole, or port, through the center that aligns with the pipeline when the valve is open, allowing fluid to pass through. When the valve is closed, the ball is rotated 90 degrees, blocking the flow. This simple yet effective mechanism provides reliable performance in managing the direction and flow of liquids and gases.

Key Features of Ball Valves

1. Materials Ball valves are commonly made from a variety of materials, such as stainless steel, brass, plastic, and carbon steel. The choice of material depends on the application and the specific requirements, such as resistance to corrosion and high temperatures.

2. Sealing Mechanism Ball valves typically utilize soft seals made from elastomers or PTFE (Teflon) to ensure a tight seal when closed. This design minimizes the risk of leaks and allows for high-pressure applications.

3. Versatility Ball valves can handle a wide range of fluids, including water, oil, gas, and chemicals. This versatility makes them suitable for various industries, including oil and gas, water treatment, food processing, and pharmaceuticals.

Advantages of Ball Valves

ball valve

1. Rapid Operation One of the most significant advantages of ball valves is their quick operation. With just a quarter turn, users can open or close the valve, allowing for fast control over fluid flow.

2. Low Pressure Drop Ball valves typically offer a low resistance to flow when opened, resulting in minimal pressure drop across the valve, which helps maintain system efficiency.

3. Durability Ball valves are built to last. Their robust design and construction make them resistant to wear and tear, and they can function effectively in both low and high-pressure environments.

4. Easy Maintenance Most ball valves require minimal maintenance. In many instances, they can be operated and maintained using basic tools, leading to reduced operational downtime.

Applications of Ball Valves

Ball valves are used in various applications, including

- Water Supply Systems They are integral in controlling the flow of water in municipal and industrial water supply systems. - Oil and Gas Industry Ball valves play a crucial role in managing the flow of hydrocarbons, ensuring safety and efficiency. - Chemical Processing In chemical plants, ball valves manage the flow of volatile substances, where precise control is paramount.

In conclusion, ball valves are a critical component in fluid control systems across multiple industries. Their efficient design, reliable performance, and ease of maintenance make them a go-to solution for engineers and maintenance professionals alike. Understanding their features and applications is essential for anyone involved in fluid management or engineering.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024