1 月 . 29, 2025 00:55 Back to list

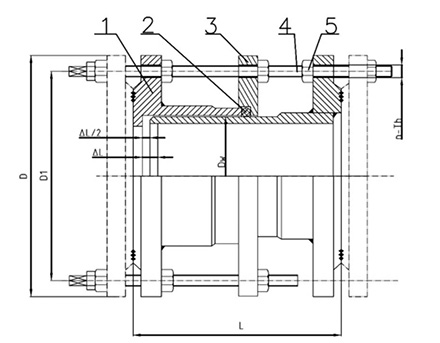

ball type foot valve

Ball type foot valves are an essential component in various industrial and domestic applications, ensuring the smooth operation of fluid control systems. Designed to prevent backflow, these valves not only maintain system efficiency but also safeguard against potential damage. Their pivotal role in maintaining hydraulic integrity makes them a staple in the toolkit of engineers and technicians worldwide.

In terms of authoritativeness, ball type foot valves are often recommended by authoritative bodies in fluid dynamics and engineering due to their efficiency and longevity. This is reinforced by industry standards and certifications that these valves frequently meet or exceed. Professionals recognize these certifications as markers of quality and reliability, ensuring that the components they use will stand the test of time and operate without fail in critical applications. Trustworthiness is another key aspect, as companies that manufacture ball type foot valves often provide detailed specifications and usage guidelines. This transparency allows engineers to make informed decisions based on the valve's performance data, ensuring compatibility with existing systems. Trusted manufacturers also offer warranties and support services, adding an extra layer of confidence for purchasers investing in these critical components. For those implementing ball type foot valves, case studies and user testimonials can be particularly enlightening. Real-world experiences show how these valves perform under various conditions, highlighting their benefits and any potential challenges. For instance, in a case study involving an agricultural irrigation system, the use of a ball type foot valve resulted in a noticeable reduction in pump cycling and maintenance costs, demonstrating tangible improvements in system efficiency. Ultimately, the choice to use a ball type foot valve should be guided by a thorough understanding of the application's requirements and environmental conditions. By leveraging the expertise and insights provided by industry professionals, along with personal experience and reliable manufacturer information, users can ensure optimal system performance and longevity. Ball type foot valves remain a trusted choice for those seeking a reliable, efficient, and durable solution for their fluid control needs.

In terms of authoritativeness, ball type foot valves are often recommended by authoritative bodies in fluid dynamics and engineering due to their efficiency and longevity. This is reinforced by industry standards and certifications that these valves frequently meet or exceed. Professionals recognize these certifications as markers of quality and reliability, ensuring that the components they use will stand the test of time and operate without fail in critical applications. Trustworthiness is another key aspect, as companies that manufacture ball type foot valves often provide detailed specifications and usage guidelines. This transparency allows engineers to make informed decisions based on the valve's performance data, ensuring compatibility with existing systems. Trusted manufacturers also offer warranties and support services, adding an extra layer of confidence for purchasers investing in these critical components. For those implementing ball type foot valves, case studies and user testimonials can be particularly enlightening. Real-world experiences show how these valves perform under various conditions, highlighting their benefits and any potential challenges. For instance, in a case study involving an agricultural irrigation system, the use of a ball type foot valve resulted in a noticeable reduction in pump cycling and maintenance costs, demonstrating tangible improvements in system efficiency. Ultimately, the choice to use a ball type foot valve should be guided by a thorough understanding of the application's requirements and environmental conditions. By leveraging the expertise and insights provided by industry professionals, along with personal experience and reliable manufacturer information, users can ensure optimal system performance and longevity. Ball type foot valves remain a trusted choice for those seeking a reliable, efficient, and durable solution for their fluid control needs.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024