10 月 . 09, 2024 10:07 Back to list

Air Control Valve for Efficient Fluid Regulation and Management Solutions

The Importance of Air Valves in Modern Technologies

Air valves play a crucial role in various applications, serving as integral components in systems that require precise management of airflow. From HVAC (heating, ventilation, and air conditioning) systems to pneumatic machinery, the efficient operation of air valves can significantly influence overall system performance and energy efficiency.

At their core, air valves are designed to control the flow of air in and out of a system

. By regulating airflow, these valves can help maintain optimal pressure levels, reduce energy consumption, and enhance the safety of equipment. There are several types of air valves, each suited to different applications and operational requirements. The most commonly used types include solenoid valves, pneumatic valves, and manual valves, each offering unique advantages.Solenoid valves, for example, are electrically actuated and provide quick response times, making them ideal for automated systems. They are often utilized in HVAC systems to regulate temperature and air distribution efficiently. These valves can open and close rapidly, ensuring that the air is directed where it is most needed, thus enhancing the system’s overall efficiency.

Pneumatic valves, on the other hand, are often used in industrial applications where compressed air is employed to power machinery. These valves control the flow of compressed air to various parts of the machinery, allowing for smooth operation and precise control of movements. The type of pneumatic valve chosen depends on the specific requirements of the application, such as the need for speed, precision, and flow capacity.

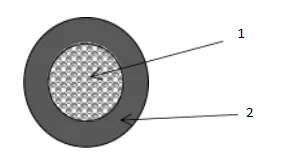

air valve

Manual valves, while less common in automated systems, are still widely used in applications where human oversight is necessary. These valves allow operators to open or close air passages as needed, providing a straightforward solution for controlling airflow during maintenance or system adjustments.

In addition to their functional capabilities, air valves also play a vital role in ensuring safety. In applications involving high pressures or hazardous materials, malfunctioning air valves can lead to catastrophic failures. Therefore, regular maintenance and inspections of air valves are essential to prevent such incidents. Furthermore, using high-quality materials and designs can greatly enhance the durability and reliability of these valves, contributing to overall system safety.

Energy efficiency is another critical aspect of air valve operation. With growing concerns about energy consumption and environmental impacts, many industries are seeking ways to optimize their systems. Properly functioning air valves can reduce energy waste by ensuring that systems operate within their intended parameters. This not only saves on operational costs but also aligns with global sustainability goals.

In conclusion, air valves are indispensable components in a wide variety of modern technologies. Their ability to control airflow is critical for maintaining operational efficiency, ensuring safety, and reducing energy consumption. As industries continue to evolve and adopt more sophisticated technologies, the role of air valves will only grow in importance. Investing in high-quality air valves and maintaining them regularly is essential for achieving optimal performance across various applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024