9 月 . 28, 2024 20:28 Back to list

Air Control Mechanism for Enhanced Performance and Efficiency in Systems

Understanding Air Valves Essential Components for Fluid Control

Air valves play a crucial role in various industries by regulating air flow in pneumatic systems, ensuring optimal performance and safety in different applications. These valves are designed to manage the pressure and volume of air, enabling machines and equipment to function efficiently.

At its core, an air valve is a mechanical device that opens, closes, or partially obstructs the flow of air within a system

. They can be categorized into several types, including manual, automatic, and solenoid-operated valves. Each type serves specific purposes and is selected based on the requirements of the application.Manual Air Valves are operated by hand and are typically used in systems where frequent adjustment of air flow is needed. They are straightforward in design, allowing operators to easily control the flow rate by turning a knob or lever. These valves are often found in smaller systems, where budget constraints and simplicity are paramount.

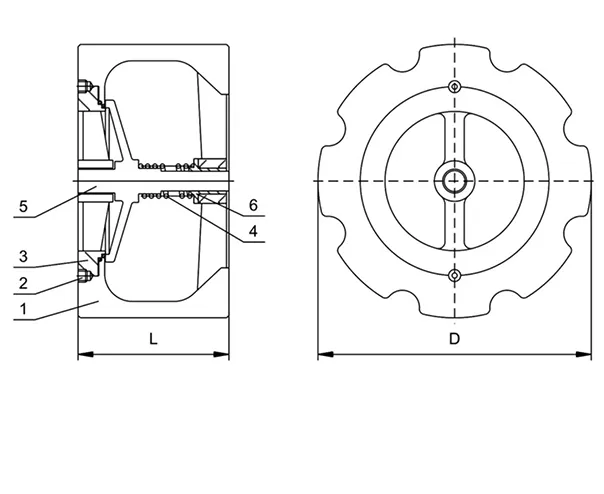

air valve

Automatic Air Valves are designed to respond to specific conditions without human intervention. These valves can utilize different mechanisms, such as pressure differentials, to open or close. They are widely used in applications where constant monitoring and adjustment of air flow are necessary, such as in HVAC systems or pneumatic actuators in manufacturing plants.

Solenoid Air Valves are a subtype of automatic valves that are electrically operated. When an electrical current passes through the solenoid coil, it generates a magnetic field that moves a plunger, either opening or closing the valve. This type of valve is commonly found in automated systems, providing rapid response times that are essential for applications requiring precise control.

The importance of air valves extends beyond just managing air flow; they also contribute to the overall efficiency and safety of systems. Properly functioning air valves can prevent excess pressure build-up, reducing the risk of system failures or accidents. Additionally, regular maintenance of these valves ensures longevity and reliable performance, which is vital for industries reliant on pneumatic technology.

In summary, air valves are critical components in fluid control systems across various sectors. Understanding their functions, types, and maintenance needs allows businesses to optimize their operations, enhance safety measures, and improve overall efficiency. Whether in manufacturing, HVAC, or pneumatic applications, the significance of these valves cannot be overstated in ensuring smooth and safe air flow management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024