10 月 . 18, 2024 10:29 Back to list

Air Control Mechanism for Enhanced Performance and Efficiency

Understanding Air Valves Importance and Applications

Air valves are critical components in various engineering fields, particularly in fluid dynamics, pneumatics, and automotive systems. These devices serve to manage the flow of air, ensuring optimal performance and efficiency in numerous applications. The significance of air valves extends across multiple sectors, including aerospace, manufacturing, HVAC systems, and even everyday household appliances.

What is an Air Valve?

An air valve is a mechanical device designed to control the passage of air in a system. It can either allow air to pass through or block it, depending on the application's requirements. Air valves come in various designs and mechanisms, such as manual, automatic, and electronically controlled versions. They are typically used to regulate airflow, maintain pressure, and prevent contamination in air systems.

Applications of Air Valves

1. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, air valves play a crucial role in maintaining indoor comfort. These valves help regulate the airflow to different parts of a building, ensuring that each area receives adequate heating or cooling. By adjusting the air distribution, HVAC air valves enhance energy efficiency and optimize the overall performance of climate control systems.

2. Automotive Industry Air valves are integral to the proper functioning of an automobile's engine. These valves regulate the intake of air into the combustion chamber, which is critical for maintaining the optimal air-to-fuel ratio. This regulation affects engine performance, fuel efficiency, and emission levels. Advanced vehicles may utilize electronic air valves for precise control, contributing to better engine management and responsiveness.

3. Aerospace Applications In the aerospace industry, air valves are essential for managing the airflow in various systems, including cabin pressure control and fuel systems. The proper functioning of air valves ensures passenger safety and comfort at high altitudes. Additionally, air valves are used in braking systems of aircraft, where they control the pneumatic pressure needed for effective braking.

4. Industrial Machinery Many industrial processes rely on pneumatic systems that use air valves to control the operation of machinery. In manufacturing settings, air valves provide automation by regulating the flow of compressed air to actuators and cylinders. This automation increases productivity, enhances safety, and reduces labor costs.

air valve

Types of Air Valves

Air valves can be categorized based on their operation and mechanism. Some common types include

- Ball Valves These valves use a spherical obstruction to allow or block airflow. They are known for their durability and reliability and are commonly used in high-pressure applications.

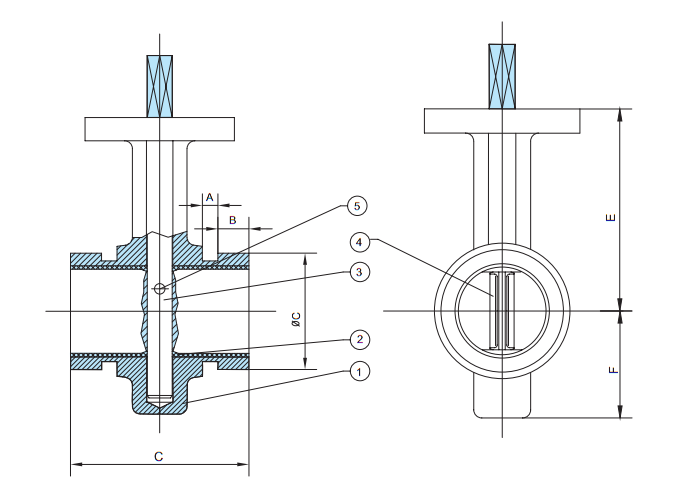

- Butterfly Valves Featuring a rotating disc, butterfly valves control airflow with minimal resistance. They are particularly popular in large-scale industrial applications due to their lightweight and compact design.

- Solenoid Valves These are electromagnetic valves that open and close in response to an electrical signal. Solenoid valves are widely used in automation and control systems, providing quick and precise operation.

- Check Valves Designed to prevent backflow, check valves allow air to flow in one direction only. They are vital in applications where reverse airflow could cause damage or inefficiencies.

Conclusion

In conclusion, air valves are indispensable components that play a significant role in various applications across multiple industries. They help maintain airflow, regulate pressure, and ensure system efficiency, making them crucial for the functionality of HVAC systems, automotive engines, aerospace technology, and industrial machinery. As technology advances and the demand for efficient systems continues to grow, the development and implementation of air valves will remain pivotal in optimizing performance and ensuring reliability in air management systems. Understanding their functionality and applications can help engineers, technicians, and manufacturers design better systems and achieve greater efficiencies in their operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024