9 月 . 24, 2024 21:31 Back to list

Air Pressure Venting System for Optimal Safety and Performance Management in Equipment

Understanding Air Pressure Release Valves Functionality and Importance

Air pressure release valves, often referred to as pressure relief valves (PRVs), play a crucial role in various industrial and mechanical systems. Their primary function is to prevent the potentially dangerous build-up of pressure within a system. When pressure exceeds a predetermined threshold, these valves automatically release excess pressure, thereby protecting equipment and maintaining operational safety.

How Do Air Pressure Release Valves Work?

The basic mechanism of an air pressure release valve is relatively simple. It consists of a spring-loaded disc or diaphragm that holds back pressure until it reaches a certain level. When the internal pressure rises above this threshold, the force exerted by the gas or liquid overcomes the spring tension, causing the valve to open. This action allows the excess pressure to be vented safely to the atmosphere or redirected within the system, thereby reducing the pressure to acceptable levels.

The valves are designed to close automatically once pressure returns to safe limits, ensuring that the system can continue to operate without manual intervention. This automatic reset feature is vital for ensuring ongoing safety and functionality in high-pressure environments, such as in boilers, compressors, and other pressurized vessels.

Applications of Air Pressure Release Valves

Air pressure release valves are widely used across various industries, including oil and gas, chemical processing, and manufacturing. In the oil and gas sector, these valves protect pipelines and storage tanks from overpressure situations that could lead to catastrophic failures or leaks. In chemical processing facilities, PRVs are essential for maintaining safe operating conditions in reactors and distillation columns, where pressure fluctuations can occur due to temperature changes or chemical reactions.

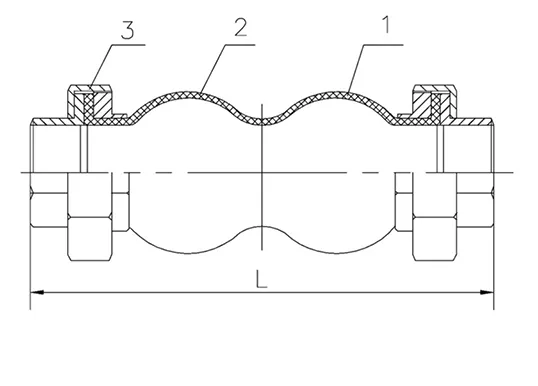

air pressure release valve

Moreover, in HVAC systems, these valves are crucial for maintaining optimal system performance. By regulating pressure within air ducts and components, they ensure efficient operation and prevent damage to equipment caused by overpressure.

Importance of Regular Maintenance

While air pressure release valves are designed to operate automatically and effectively, regular maintenance is necessary to ensure their reliability. Over time, debris, wear, and corrosion can affect the valve's performance, leading to malfunctions. Regular inspections and maintenance schedules can help identify potential issues before they result in system failures or safety hazards.

Operators should pay close attention to the manufacturer's guidelines for maintenance intervals and procedures. Testing the valves for proper functioning involves simulating operating conditions to verify that they open and close at the specified pressure settings.

Conclusion

In conclusion, air pressure release valves are critical components in many industrial systems, offering a straightforward yet effective means to manage pressure surges. Their automatic operation enhances safety and reliability, making them indispensable in various applications. By understanding their function and committing to regular maintenance, industries can ensure optimal performance and safety, ultimately leading to more efficient and secure operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024