10 月 . 08, 2024 16:48 Back to list

Air Pressure Regulation Valve for Optimal System Performance and Control Efficiency

Air Pressure Control Valve A Vital Component in Pneumatic Systems

Air pressure control valves are essential devices used in various pneumatic systems to regulate air pressure and ensure optimal performance. These valves play a crucial role in maintaining the desired pressure levels within a system, ultimately affecting the efficiency, safety, and reliability of the equipment involved.

At its core, an air pressure control valve is designed to modulate the flow of compressed air within a system. By adjusting the opening and closing of the valve, it can maintain a specific pressure threshold, preventing over-pressurization or under-pressurization. This capability is particularly important in applications such as manufacturing, where precise control of air pressure directly impacts the operation of pneumatic tools, actuators, and other machinery.

One of the key features of air pressure control valves is their ability to respond to changes in system pressure. Many modern valves come equipped with advanced sensors and control systems that allow them to automatically adjust in real time. This is vital for ensuring that the pressure remains within the optimal range, which improves the efficiency of the pneumatic system and reduces the risk of equipment damage. For instance, if the pressure in a system rises above the predetermined threshold, the valve can immediately close to prevent potential hazards.

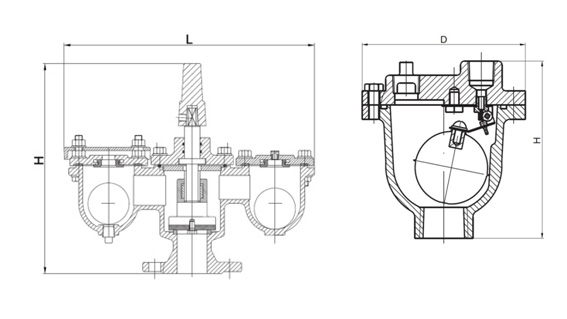

air pressure control valve

Air pressure control valves are available in various types and designs, including proportional valves, pressure-reducing valves, and pilot-operated valves. Proportional valves allow for fine-tuned control over the airflow and pressure, making them suitable for applications that require precise adjustments. Pressure-reducing valves, on the other hand, are specifically designed to decrease high input pressure to a lower, usable level, ensuring that downstream equipment operates safely. Pilot-operated valves leverage a small pilot signal to control a larger main valve, providing enhanced efficiency in larger systems.

The materials used in the construction of air pressure control valves also play a significant role in their performance and longevity. Common materials include brass, stainless steel, and various durable plastics. The choice of material often depends on the specific application, including factors such as operating temperature, pressure range, and exposure to corrosive substances.

In conclusion, air pressure control valves are indispensable components of pneumatic systems, helping to manage the flow and pressure of compressed air effectively. Their ability to maintain optimal pressure levels enhances the performance and safety of various industrial applications. As technology continues to advance, the functionality and efficiency of these valves are expected to improve, making them even more integral to the engineering and manufacturing sectors. Whether in factory automation, robotics, or any application relying on pneumatic power, understanding and utilizing air pressure control valves will be crucial for achieving reliability and optimum performance.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024