2 月 . 18, 2025 05:19 Back to list

air pressure control valve

Air pressure control valves play a pivotal role in various industrial and commercial applications, ensuring that systems function optimally and safely. These components are integral to managing the air pressure in pneumatic systems, preventing machinery from over-pressurization and attendant risks. This article delves deep into the facets that make air pressure control valves indispensable, drawing from real-world experience and expert insights.

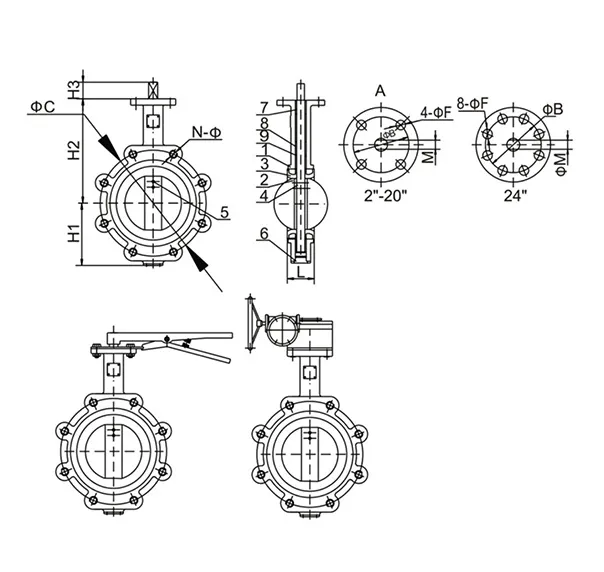

From a technical standpoint, the expertise involved in the development of air pressure control valves is highly specialized. Many manufacturers offer advanced models that incorporate digital controls, enabling more precise adjustments and integration with automated systems. This evolution in valve technology signifies a shift toward more intelligent, responsive pneumatic systems, spurred by growing demand for efficiency and precision in industrial operations. A cornerstone of authoritative advice on air pressure control valves is regular maintenance and inspection. Even the highest quality valves can suffer from wear and tear, necessitating regular checks to prevent leaks or blockages that could compromise system performance. Our experiences underscore the importance of implementing a preventive maintenance schedule—by doing so, you can preemptively address potential issues that could escalate into costly repairs or replacements. Trust in the performance of air pressure control valves is built upon a foundation of compliance with established industry standards. When selecting a valve, ensuring that it is certified by recognized standards not only vouches for its quality but also its safety in operation. Certifications such as ISO, ANSI, or various government regulations provide a benchmark that reassures users of the valve’s reliability and integrity. In conclusion, air pressure control valves are a critical component in the ecosystem of pneumatic systems. Their ability to control, regulate, and sustain air pressure efficiently is vital to the operation of machinery across numerous industries. Through expert selection, diligent maintenance, and compliance with authoritative standards, these valves uphold the trust placed in them, delivering consistent and reliable performance. The future holds even more promising developments as technology continues to refine these indispensable components, underscoring their role in modern industrial landscapes.

From a technical standpoint, the expertise involved in the development of air pressure control valves is highly specialized. Many manufacturers offer advanced models that incorporate digital controls, enabling more precise adjustments and integration with automated systems. This evolution in valve technology signifies a shift toward more intelligent, responsive pneumatic systems, spurred by growing demand for efficiency and precision in industrial operations. A cornerstone of authoritative advice on air pressure control valves is regular maintenance and inspection. Even the highest quality valves can suffer from wear and tear, necessitating regular checks to prevent leaks or blockages that could compromise system performance. Our experiences underscore the importance of implementing a preventive maintenance schedule—by doing so, you can preemptively address potential issues that could escalate into costly repairs or replacements. Trust in the performance of air pressure control valves is built upon a foundation of compliance with established industry standards. When selecting a valve, ensuring that it is certified by recognized standards not only vouches for its quality but also its safety in operation. Certifications such as ISO, ANSI, or various government regulations provide a benchmark that reassures users of the valve’s reliability and integrity. In conclusion, air pressure control valves are a critical component in the ecosystem of pneumatic systems. Their ability to control, regulate, and sustain air pressure efficiently is vital to the operation of machinery across numerous industries. Through expert selection, diligent maintenance, and compliance with authoritative standards, these valves uphold the trust placed in them, delivering consistent and reliable performance. The future holds even more promising developments as technology continues to refine these indispensable components, underscoring their role in modern industrial landscapes.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024