9 月 . 25, 2024 00:27 Back to list

Understanding Air Compressor Release Valves and Their Importance in Safe Operation

Understanding Air Compressor Release Valves

Air compressors play a vital role in various industries and home applications, providing a convenient source of compressed air for tools and machinery. Among the essential components of an air compressor is the release valve, often referred to as the safety valve. This component is critical for ensuring the safe operation of the compressor by preventing overpressure situations that could lead to equipment failure or even accidents.

What is a Release Valve?

A release valve is a safety device designed to automatically vent excess pressure from the air compressor’s tank. As the compressor builds up pressure during operation, the release valve ensures that the pressure does not exceed a set limit. When the internal pressure reaches this threshold, the valve opens, allowing air to escape, thereby preventing potential explosions or other hazardous incidents.

Importance of the Release Valve

The primary function of the release valve is safety. Air compressors operate by compressing air to store it in a tank for later use. If the compressor malfunctions or if there’s a block in the system, the pressure within the tank can rise dangerously high. The release valve acts as a fail-safe mechanism, ensuring that if the pressure exceeds a pre-defined level, the system can relieve that pressure before it becomes catastrophic.

Additionally, the release valve contributes to the overall efficiency of the compressor system. By preventing excessive pressure buildup, it helps maintain optimal performance and prolongs the lifespan of the compressor. Regular maintenance of the release valve, including inspection for wear and tear, is therefore crucial for the ongoing safety and functionality of the unit.

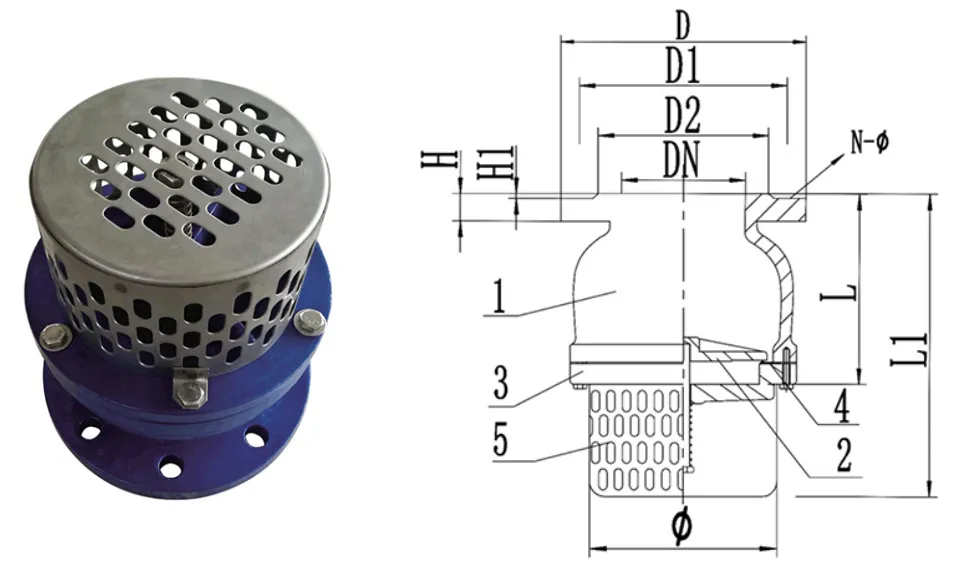

air compressor release valve

Types of Release Valves

There are several types of release valves, with the most common being the spring-loaded valve. This type of valve uses a spring mechanism to hold a cover closed against the pressure in the tank. When the pressure exceeds the spring tension, the cover opens, allowing air to escape. Other types include pilot-operated valves and electric release valves, which can offer more precise control over pressure release.

Maintenance Tips

To ensure that your air compressor’s release valve operates effectively, regular maintenance is essential. Here are a few tips

1. Regular Inspection Check the release valve frequently to ensure it is functioning properly. Look for signs of wear, corrosion, or blockages. 2. Test the Valve Periodically test the valve by manually activating it, if applicable. It should open smoothly without any obstruction. 3. Keep it Clean Ensure the area around the valve is clean and free from debris that could hinder its operation. 4. Consult the Manual Always refer to the manufacturer’s manual for specific maintenance guidelines related to your compressor model.

Conclusion

In summary, the release valve of an air compressor is a crucial component that ensures safety during operation. Understanding its function, types, and maintenance requirements can help users ensure their equipment operates efficiently and safely. By prioritizing the upkeep of the release valve, users can minimize risks and extend the life of their air compressor, making it a safer and more reliable tool for any application.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024