10 月 . 18, 2024 22:43 Back to list

Understanding the Functionality and Applications of Actuated Valves in Fluid Control Systems

Understanding Actuated Valves Essential Components in Modern Automation

Actuated valves are integral components in various industries, including oil and gas, water treatment, and manufacturing. These devices function as automated control mechanisms, allowing for the regulation of fluid flow within a system. The actuator, which can be electric, pneumatic, or hydraulic, provides the necessary force to open and close the valve, ensuring precise control over the fluid dynamics.

At their core, actuated valves combine a traditional valve—like a ball, globe, or butterfly valve—with an actuator. This combination enables various operational configurations, enhancing system efficiency and reliability. The seamless integration of these components is crucial for processes requiring continuous monitoring and adjustments, such as in industrial manufacturing where maintaining specific flow rates can be pivotal for product quality.

One key benefit of actuated valves is their ability to improve safety. In many applications, manual operation of valves can pose risks, especially in high-pressure or hazardous environments. Actuated valves can be monitored and controlled remotely, allowing operators to make adjustments from a safe distance. This capability reduces the likelihood of accidents and makes it easier to adhere to safety regulations and best practices.

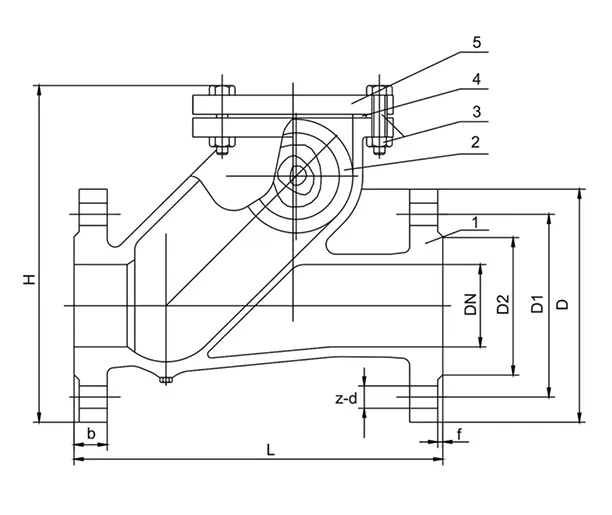

actuated valve

Moreover, actuated valves contribute significantly to energy efficiency

. By precisely controlling the flow of fluids, they help to minimize waste and optimize energy consumption. For instance, in HVAC systems, smart actuated valves can adjust the flow of hot or cold water according to real-time temperature readings, thereby reducing energy costs and improving the overall comfort of indoor spaces.In recent years, technological advancements have led to the development of smarter actuated valve systems. Integration with Internet of Things (IoT) technology allows for real-time data collection and analysis, facilitating predictive maintenance and further enhancing operational efficiency. These modern systems can alert operators to potential issues before they escalate, ensuring continuous uptime and reducing maintenance costs.

The selection of an appropriate actuated valve depends on several factors, including the nature of the fluid being controlled, the required flow rate, and environmental conditions. It is essential for engineers and operators to consider these aspects carefully to ensure they choose the most suitable valve type and actuator combination for their specific use case.

In conclusion, actuated valves play a crucial role in contemporary automation technology, offering enhanced safety, energy efficiency, and operational flexibility. As industries continue to evolve, the importance of these devices will only grow, driving innovation and efficiency in fluid control systems worldwide.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024